People who are into 3D printers, whether they’re new or experienced, sometimes face a common issue: 3D prints not sticking to the printer’s bed. This problem can happen for many reasons, like the bed not being level or the temperature not being correct.

This article will help you understand why this issue occurs and provide a step-by-step guide to resolve it.

Table of Contents

Why your 3D prints are not sticking to print bed?

There could be many reasons why your 3D print is not sticking to the bed. Some of the most common reasons are: improper bed leveling, incorrect bed temperature, plastic debris on the print bed, the print speed being too fast, or not using adhesives properly.

Here are the 5 Reasons and ways to fix the bed adhesion problem

1. Cleaning the Print Bed

To make sure your print sticks well, it is important to have a clean print bed. Even if you can’t see it, tiny bits of dust, oil, or other particles can get in the way and make it hard for the melted filament to stick properly.

Cleaning the bed is simple. If you can take the build plate off your 3D printer, just remove it and wash it in the sink. Then dry it with a clean towel. If your build plate is non-removable, then you can also use isopropyl alcohol; just spray it on the build plate and wipe it with a cloth.

Should you clean your bed with water or isopropyl alcohol?

- To clean your 3D Printer’s Build Plate, isopropyl alcohol is preferred over water. Isopropyl alcohol evaporates quickly, leaving no residue and ensuring a clean surface for printing. On the other hand, using water can help you remove more stubborn residues easily, like extra adhesives, which are pretty hard to remove using isopropyl alcohol.

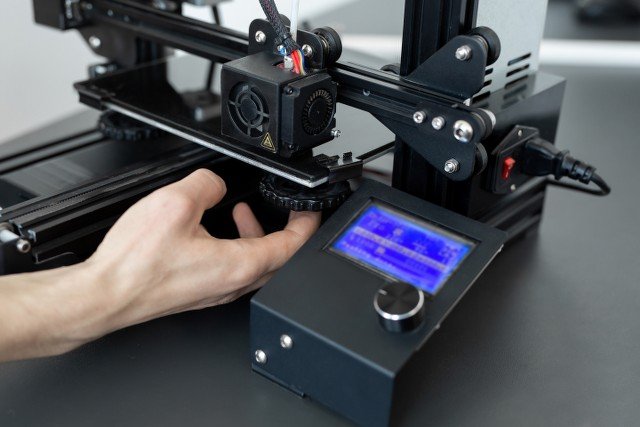

2. Correcting bed leveling

A common issue that beginners face is also a big reason why most prints don’t stick well: the bed is not properly leveled. If the print bed is not leveled, one corner might be too close to the nozzle, while another is too far. This makes it hard for the print to stick evenly across the bed.

How to fix the bed leveling problem

If your 3D printer has an Auto Bed Leveling (ABL) sensor, it will take care of leveling for you.

For printers without auto bed leveling, follow these steps:

- Clean the nozzle and remove any plastic from the tip of the nozzle.

- Auto home the 3D printer.

- Disable the stepper motors.

- Place a piece of paper

- Move the print head to the first corner.

- Gently slide the paper between the nozzle and the bed.

- Adjust the bed’s screws to create slight friction when moving the paper.

- Repeat this process for all four corners.

- Bring the print head to the center and verify if the paper experiences similar resistance. If it does, the bed is now properly leveled.

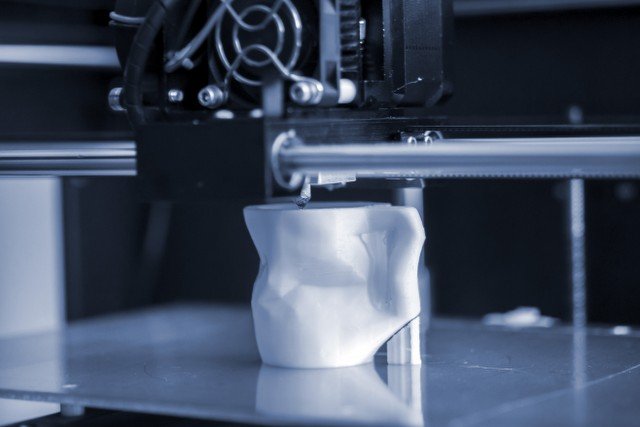

3. Adjusting printing speed

Fast 3D printing sounds tempting, but it can hurt your bed adhesion. While plastic bonds easily to layers of plastic, that very first layer has to grip a completely different surface—whether it’s glass, a PEI sheet, or even tape

To make sure the bottom of your 3D print sticks well to the bed, especially at the beginning when the first layers are being made, slow down the printing speed. Starting slowly helps the melted plastic to stay soft for a longer time.

This helps the print stick better to the bed. If you print too fast, the plastic might not stick properly, and your print could come loose as it continues.

4. Bed temperature considerations

A lot of beginners overlook bed temperature, but it plays a huge role in getting good adhesion. The bed needs to be heated to match the filament you’re using. If the temperature isn’t right for the material, your print might struggle to stick properly

To fix this, it’s a good idea to check the guidelines from the maker of your 3D printer. They usually give you the right temperature settings for the type of material you’re using for your print.

| Material | Nozzle Temp (°C) | Print bed Temp (°C) | Fan Speed (%) |

| PLA (Polylactide) | 190-210 | 60-70 | 100 |

| ABS (Acrylonitrile Butadiene Styrene) | 230-250 | 90-100 | 50-75 |

| PETG (Polyethylene Terephthalate Glycol) | 230-260 | 60-90 | 25-50 |

| HIPS (High Impact Polystyrene) | 230-240 | 90-100 | 0 |

| NYLON | 240-260 | 70-90 | 0-25 |

| TPU (Thermoplastic Polyurethane) | 210-240 | 50-70 | 50-100 |

| PVA (Polyvinyl Alcohol) | 220-230 | 65-75 | 0-50 |

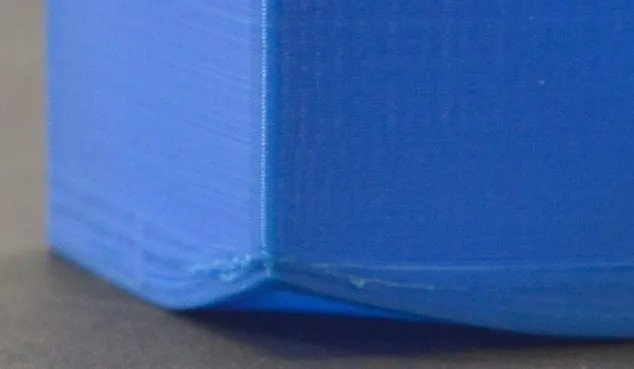

5. Using Adhesives

If you’ve tried everything and your prints are still not sticking to the bed, using adhesives could be your backup plan. Adhesives can help the print stick better and stop the corners from lifting up.

But make sure to clean the bed after every few prints to keep the dust and tiny particles away from the next print.

Note: Glue sticks and hairspray are popular and most effective adhesives for 3D printer build plates. Glue sticks create stickiness on the build plate for better adhesion, while hairspray adds a temporary adhesive layer on the glass bed.

Conclusion

There are many reasons why your 3D prints do not stick to the bed like they should. It could be because the bed is not leveled, the bed temperature is not correct or the bed might be dirty and dusty, or you’re printing initial layers at high speed. If you understand and fix these problems, you can make your 3D prints turn out much better. Follow the tips in this guide, and you’ll be able to solve these common issues and get good results every time

FAQs

Why are my 3D prints not sticking properly to the bed?

Inadequate bed adhesion can arise due to factors such as uneven bed leveling, incorrect bed temperature, unclean print surfaces, or fast printing speeds in initial layers.

How can I enhance bed adhesion for my 3D prints?

To improve bed adhesion, initiate by thoroughly cleaning the print bed to eliminate dust and debris. Focus on achieving even bed leveling, adjust printing speeds for better initial layer bonding, set accurate bed temperatures according to filament types, and consider using adhesives if necessary.

What is bed leveling, and why is it significant?

Bed leveling refers to ensuring consistent positioning of the print bed concerning the printer’s nozzle. This process is crucial to prevent issues with adhesion, as an uneven bed can lead to improper filament deposition and detachment.

Why PLA is not sticking to bed

Poor PLA bed adhesion can result from multiple issues such as incorrect bed leveling, the presence of dirt or debris, inaccurate bed temperature (recommended: hot end 190-220°C, bed 60-70°C), an improper first layer, improper first layer due to which comes out in mid printing.

How does bed temperature influence adhesion quality?

Bed temperature plays a key role in filament adhesion to the print surface. Setting the right bed temperature based on the filament material is essential, as different materials require different temperatures for proper Bed adhesion. For example, PLA (60-70°C), ABS (80-110°C), PETG (70-85°C), and TPU (20-60°C) all have specific bed temperature ranges.