Last updated on March 29th, 2024 at 06:18 pm

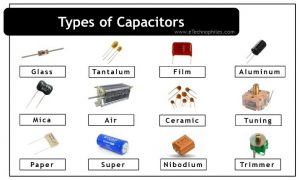

Capacitors are used in various electronic circuits and devices. Based on the application there are different types of capacitors available in the market. Hence, it becomes necessary to learn about each type before selecting one. In this article, we will discuss the most popular types and their practical applications.

List of different capacitor types

- Fixed capacitors

- Polarized

- Unpolarized

- Electrolytic capacitor

- Tantalum

- Niobium

- Aluminum

- Wet aluminum

- Manganese dioxide aluminum

- Polymer aluminum

- Super capacitors

- Double layer

- Pseudo

- Hybrid

- Ceramic capacitor

- Class 1

- Class 2

- Class 3

- Film capacitors

- Paper capacitor

- Mica capacitor

- Stacked

- Silvered

- Air capacitors

- Glass capacitors

- Variable capacitor

- Tuning

- Trimmer

- Air trimmer

- Ceramic trimmer

Table of Contents

How are capacitors classified?

A capacitor consists of two metal plates and an insulating material known as a dielectric. Depending on the type of dielectric material and the construction, various types of capacitors are available in the market.

Note: Capacitors differ in size and characteristics. For example, some capacitors, such as those used in radio circuits, are small and delicate. While capacitors found in smoothing circuits can be quite large.

Based on structure:

- Fixed

- Variable

- Trimmer

Based on polarization:

- Polarized

- Unpolarized

Now let us look at different types of capacitors in detail.

Fixed capacitors

Their capacitance value is fixed during manufacturing and cannot be changed later. They are divided into two types:

- Polarized

- Non-polarized

Polarized

They have positive and negative polarities. In a circuit, it can only be connected in only one direction. They get damaged if the polarity (direction) is reversed. They are used to achieve a high capacitive density.

These capacitors are used in DC (Direct Current applications).

The polarised capacitors are further classified into two types:

- Electrolytic

- Supercapacitors

Electrolytic

Electrolytic capacitors are polarized capacitors whose anode (positive plate) is made up of metal. And through anodization, an oxide layer is created. This oxide layer acts as the insulator (capacitor’s dielectric).

The electrolyte in the form of a solid, liquid, or gel covering the surface of this oxide layer acts as a cathode (negative plate) of the capacitor. It ensures much higher capacitance per unit volume.

Anodization is an electrochemical process that converts the metal surface into anodic oxide.

Depending on the type of metal and electrolyte used, the electrolytic capacitors are classified into the following types.

- Aluminum electrolytic capacitors – aluminum oxide (dielectric).

- Tantalum electrolytic capacitors – tantalum pentoxide (dielectric).

- Niobium electrolytic capacitors – niobium pentoxide (dielectric).

Aluminum electrolytic

They are polarized electrolytic capacitors whose anode (+ve plate) is made of pure aluminum foil with an etched surface. The aluminum forms a very thin insulating layer of aluminum oxide by anodization that acts as the dielectric of the capacitor.

A solid or a non-solid electrolyte covers the rough surface of the oxide layer, serving as the cathode (-ve plate) of the capacitor. Since the oxide layer is very thin it is possible to achieve very high capacitance.

Aluminum Electrolytic Capacitors are classified into three types based on the electrolyte used. They are:

- Wet Aluminum Electrolytic capacitors: non−solid

- Manganese dioxide Aluminum Electrolytic capacitors: solid

- Polymer Aluminum Electrolytic capacitors: solid

Characteristics:

- Much cheaper than other types of capacitors

- Available in high volumetric efficiency (0.1 microfarads to 2.2 farads)

- Rated voltage (2.5 V to 700 V)

- Large tolerance (+- 10% to +-20%)

- Higher ESR ( Effective Series Resistance), hence power dissipation is also higher.

- Lifetime is less

- Higher leakage current than ceramic and film capacitor

Applications:

- Input and output decoupling capacitors for smoothing and filtering in AC power supplies, switched-mode power supplies as well as in DC/DC converters.

- DC-link capacitors in AC/AC converters for variable frequency drive, frequency changers as well as in uninterruptible power supplies.

- Correction capacitor for power factor correction

- Energy storage for airbags, photoflash, devices, civil detonators

- Motor start capacitors for AC motors

- Bipolar capacitors for audio signal coupling

- Flash capacitors for camera flashes

Tantalum electrolytic capacitors – tantalum pentoxide (dielectric).

In this type of capacitor, tantalum metal act as an anode, and a thin tantalum oxide gets created on top of it which acts as a dielectric that is surrounded by a conductive cathode.

Tantalum capacitors are available in the lead type as well as in the chip form for surface mounting.

Characteristics:

- Capacitance is available in the range of 10nF to 100 mF.

- Due to higher relative permittivity, these capacitors have higher volumetric efficiency than aluminum capacitors. (lower in size)

- Commercially available tantalum capacitors have a rated voltage of (2 V to 500 V)

- It has higher tolerance range (+-5% to +-20%)

- Lower ESR than aluminum capacitors, hence they can withstand higher ripple currents

- They are very stable over the temperature range and reliable.

- Better shelf life

- Very sensitive to voltage polarity and voltage spikes. Hence, much care is needed while using it, or else the capacitor may get damaged.

Applications:

- Sample and hold circuits in medical devices.

- Power supply filtering on computer motherboards and cell phones due to their small size and long-term stability, most often in surface mount form.

- Military applications because they do not tend to dry out and change capacitance over time

- Audio amplifiers sometimes use tantalum capacitors where stability is a critical factor.

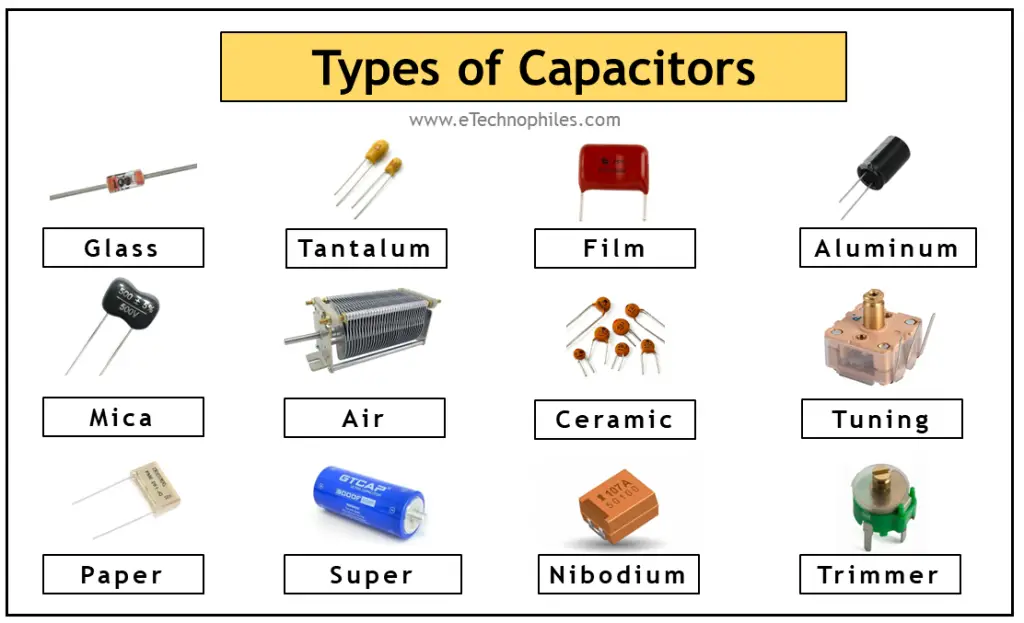

Niobium electrolytic capacitors – niobium pentoxide (dielectric).

A niobium electrolytic capacitor is a polarized capacitor whose anode (positive plate) is made of passivated niobium metal or niobium monoxide on which an insulating niobium pentoxide layer acts as the dielectric of the niobium capacitor. A solid electrolyte on the surface of the oxide layer serves as the cathode or the (negative plate) of the capacitor.

Note: It is available in SMD (Surface Mount Chip) chip capacitors and is used instead of tantalum capacitors for certain voltage and capacitance ratings.

Manufactures specify special circuit design rules for the safe operation of niobium capacitors.

Characteristics:

- Volumetric efficiency is slightly lower than the tantalum capacitor due to the lower density of niobium.

- Lower cost and better availability as the niobium ore are abundant in nature.

- High-temperature coefficient

- It possesses a lower maximum rated voltage

Applications:

- Consumer items including home theatre systems and game controllers

- Industrial facilities with improved safety features including smoke detectors and security electronics

- Automobiles include cabin electronics and telematics.

- Aircraft includes onboard entertainment telematics, defense

Super capacitors

A supercapacitor is an electrochemical capacitor that has a very high energy density as compared to a common capacitor (about 100 times greater). It is also known as an ultracapacitor. Their capacitance ranges from 100 Farad to 5K Farad.

Types

- Double layer capacitor (stores charge electrostatically)

- Pseudo–capacitor (store charge electrochemically)

- Hybrid capacitor (store charge electrostatically and electrochemically)

Electrochemical capacitors consist of two electrodes separated by an ion-permeable membrane (separator) and an electrolyte electrically connecting both electrodes. When the voltage is applied ions in the electrolyte form electric double layers of opposite polarity to the electrode’s polarity.

Characteristics:

- It stores a high amount of energy

- It possesses high capacitance

- It has high rates of charge and discharge

- Little degradation over thousands of cycles

- It has low toxicity

- Good reversibility

- It has high cycle efficiency of 95% or more

Applications:

- Due to its very fast charging and discharging it makes a great tool for regenerative braking in vehicles

- They are used in electric vehicles(EVs) to extend the life of batteries.

- They provide burst power in stop-and-go vehicles (eg. in buses and trains)

- They are used to power emergency systems in aircraft.

- It is used in the startup mechanism of automobiles

- It is used in diesel engine start-up in submarines and tanks

- It is used in the missiles backup power system

- It has the capacity to act as a power source for laptops, and flash in camera as it has backup and UPS system

- It is used in consumer electronics such as the voltage stabilizer

Note: China is experimenting with a new type of electric bus that runs without power lines, but instead uses energy stored in large supercapacitors. These capacitors are quickly replenished anytime the bus stops at any bus stop and become fully charged at the terminus.

Supercapacitors are functionally similar to a polarized capacitors (at the schematic level). Hence its symbol is the same as of polarized capacitor.

Non-polarized capacitors

A non-polarized capacitor is a type of capacitor that has no defined polarity. It can be connected in either way in a circuit. They are mainly used in circuits of coupling, decoupling, feedback, compensation, and oscillation.

These capacitors are mostly used in AC (Alternating Current applications).

The non-polarised capacitors are further classified into three types:

- Ceramic

- Film

- Other

Ceramic capacitor

The ceramic capacitor is one of the most commonly used capacitors. It is a fixed value capacitor in which ceramic acts as the dielectric. It consists of two or more alternating layers of ceramic and a metal layer acting as the electrodes. It is available in the lead form and surface mount form.

Ceramic capacitors, especially the multilayer style (MLCC), are the most manufactured and used capacitors in electronics. MLCC is made up of alternating layers of the metal electrode and ceramic as the dielectric. And due to this type of construction, the resulting capacitor consists of many small capacitors connected in a parallel connection.

Multilayer ceramic chip capacitors were the driving force behind the conversion of electronic devices from through-hole mounting to surface mounting technology in the 1980s.

Ceramic capacitors of special shapes and styles are used as the capacitors for RFI/EMI suppression, as feed-through capacitors, and in larger dimensions as power capacitors for transmitters.

Based on the working temperature range, temperature drift, and tolerance, ceramic capacitors are divided into three classes:

- Class 1

- Class 2

- Class 3

Class 1

- It offers high stability and low losses for resonant circuit applications

- They are accurate and temperature compensating capacitors

- They offer the most stable voltage, temperature and frequency (to some extent)

- They have a low tolerance value of +- 5%

- They have lower volumetric efficiency, hence available in low capacitance value

- They have lower ESR and leakage current

The most common compounds used as dielectrics are:

- Magnesium titanate for a positive temperature coefficient.

- Calcium titanate for capacitors with a negative temperature coefficient.

Class 2

- This type of capacitor possesses high permittivity resulting in better volumetric efficiency than class 1 capacitors.

- It has lower accuracy and stability for smoothing, by-pass, coupling and decoupling applications

- It exhibits a non-linear temperature coefficient

Class 3

- They are barrier layer or semi conductive ceramic capacitors that have very high permittivity (up to 50000) and a better volumetric efficiency than class 2 capacitors.

- It has the worst electrical characteristics including lower accuracy and stability.

- Dielectric is characterized by a very high nonlinear change of capacitance over the temperature range.

Applications:

- They are used in the resonant circuit in transmitter stations.

- Class 2 high-power capacitors: high voltage laser power supplies, power circuit breakers, induction furnaces, etc.

- Because of their non-polarity and wide range of capacitances, voltage ratings, and sizes, ceramic capacitors can also be utilized as general-purpose capacitors.

- Depending on the application, MLCC used in printed circuit boards (PCB) are rated for voltages ranging from just a few volts to several hundreds of volts.

- They are used to separate AC components from DC + AC components and only transmit AC components, not DC components.

- They are also used in decoupling, smoothing, and filtering.

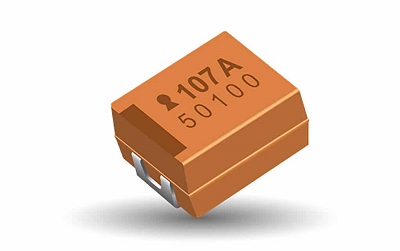

Film capacitors

Film capacitors consist of plastic film as a dielectric material. There are different types of film capacitors depending on the different types of film materials

- Polypropylene

- Polyester

- Polystyrene

The capacitor is not polarized, it is appropriate for AC signal and power applications.

Characteristics:

- It is constructed with high-accuracy capacitance values.

- They have a very low average failure rate, a long shelf life, and a long service life.

- In comparison to other types, film capacitors may be produced with extremely high precision capacitance values and maintain such values for a longer time.

- It can withstand kilovolt voltages and provide incredibly powerful surge current bursts.

Applications:

- They can be used in more conventional applications including filters, audio crossovers, and voltage smoothing capacitors. Energy can be stored in it and then released when needed in the form of a high-current pulse.

- They have lower distortion factors, ESR, and ESL values. It is therefore a better choice for high-voltage and high-frequency applications.

- They are frequently used in circuits for first- or second-order filtering, high-frequency bypass, and high-frequency filtering.

- It is widely used in a variety of industries, including electronics, home appliances, telecommunications, electric power, electrified trains, hybrid autos, wind power, solar power, and many more.

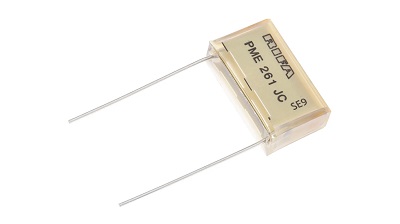

Paper capacitor

It is a fixed capacitor that consists of two metallic plates with paper acting as their dielectric.

Characteristics:

- They have a lot of leakage current.

- Thin dielectric thickness (often only 6-20m) and strong tensile strength allow them to be coiled into a large-capacity and small-volume capacitor with a capacitance of 1–20F.

- The working voltage is high, and the capacitance range is broad.

- Lacks thermal and chemical stability, which makes it prone to aging.

- Normally, the working temperature ranges from 85 to 100 degrees Celsius.

- It is not appropriate for use in high-frequency circuits due to its hygroscopic nature and need for sealing.

- Low production costs and a straightforward method.

- DC and low-frequency circuits frequently use paper capacitors.

Other capacitors (depending on the dielectric used)

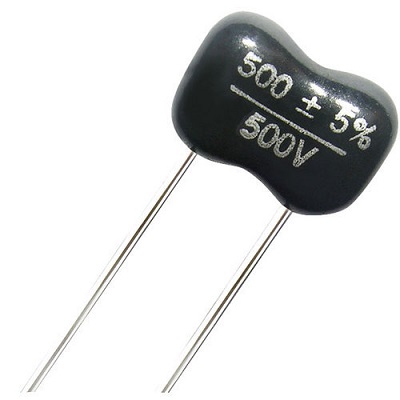

Mica capacitor

Capacitors that use mica as the dielectric are known as mica capacitors. They are constructed by sandwiching mica sheets that have a metal coating on both sides. Mica sheets made of muscovite and phlogopite are more frequently utilized. The first has superior electrical characteristics, whilst the second has a greater thermal resistance.

There are two categories of mica capacitors:

- Stacked mica

- Silvered mica

Characteristics:

- The silver mica capacitor has a tolerance range as low as 1%. This is far superior to other capacitors.

- These are precise and steady, but because there is no air gap in the design, their capacitance will eventually fluctuate slightly.

- They have low resistive and inductive losses.

- They can be used at high frequencies because their features are often frequency-independent.

- They are expensive & bulky.

Applications:

- In power RF circuits, where stability is crucial, silver mica capacitors are employed.

- These are employed in high-frequency tuned circuits like oscillators and filters. They are occasionally used in snubbers.

- Since silver mica capacitors have a high breakdown voltage, they are frequently utilized in high-voltage applications.

- High-power applications like RF transmitters employ these capacitors.

- In laser, RADAR, space, resonance circuits, coupling circuits, etc.

Air capacitors

Air serves as the dielectric in air capacitors. The simplest air capacitors have conducting plates with air between them. They are used in radio tuning applications and antenna tuning. Other applications include MRI medical scanners and RF matching networks for plasma control in conductive material deposition on silicon wafers.

Note: These capacitors can be fixed or variable; however, fixed capacitors are rarely utilized because other capacitors with better qualities are available.

Glass capacitors

These capacitors consist of aluminum electrodes with a glass dielectric.

Characteristics:

- The temperature coefficient is low.

- These capacitors are noise-free.

- They generate high quality output with little loss.

- They are able to function at high operating temperatures.

- Large RF currents may be handled by these capacitors.

Applications:

- Used in circuits where high temperature zones are required.

- Used in achieving high Q (quality factor).

- In circuits with high power handling.

- Circuits with tight tolerances are required.

Variable capacitors

A variable capacitor is a capacitor whose capacitance may be varied manually or electrically. In general, variable capacitors are made up of two sets of intertwined metallic plates, one of which is fixed and the other variable. These capacitors offer capacitance values ranging from 10 to 500 pF.

These variable resistors have a wide range of applications, including antenna impedance matching, adjusting LC circuits in radio receivers, and more.

There are two primary varieties of variable capacitors are:

- Tuning

- Trimmer

Tuning capacitor

Tuning capacitors use a frame that consists of a stator and a rotor. The frame supports both the stator and the mica material. The rotors rotate with the aid of a shaft when the stator is not in use.

Trimmer capacitor

A trimmer is a variable capacitor but small in size. They are used in devices where the capacitance value is fixed during manufacturing and needs no manual adjustment.

But with time, due to alternation in other circuit parameters, the capacitance value of the capacitor may change. In such a scenario, this small trimmer capacitor can be used to re-calibrate the circuit. A screwdriver is required to adjust the capacitance of trimmer capacitors.

A trimmer capacitor has three leads:

- A common lead

- Lead that connects to the rotor

- Lead that is attached to the stationary plate

The trimmer capacitor consists of two plates that are parallel to each other. One of the plates is fixed, while the other is moveable. These are separated by the dielectric. The capacitor’s dielectric material is fixed. By adjusting the moveable plate, the distance between the plate changes. In this way, the capacitance is changed.

Based on the type of dielectric, these are classified as:

- Air trimmer

- Ceramic trimmer

Applications:

- They are used in printed circuit boards.

- These are preferred in the calibration of the equipment.

- These are used in radio receivers where the LC circuits are present.