Last updated on March 29th, 2024 at 05:04 pm

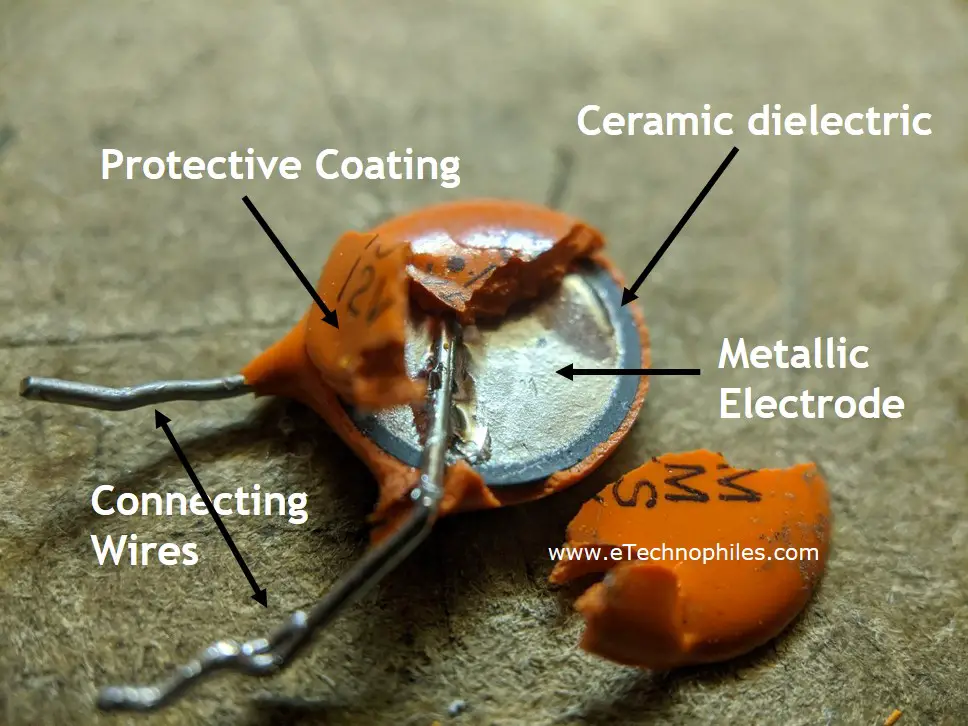

Ceramic capacitors are a class of non-polarized fixed-value electrostatic capacitors that use a variety of ceramic powder materials as their dielectric to obtain particular performance characteristics. They are used in a wide variety of electronic devices, including radios, TVs, computers, and mobile phones.

They are especially well-suited for use in high-frequency applications because they have a very low self-inductance and small physical size.

Ceramic capacitors typically have a capacitance range of 10 pF to 0.1 μF. In this article, you will learn about ceramics, capacitor construction, its types, and some frequently asked questions.

Note: Since the Ceramic capacitor does not have any polarity, it is widely used in AC circuits.

Table of Contents

What is ceramic in a ceramic capacitor?

Ceramics are inorganic, non-metallic, crystalline oxide, nitride, or carbide substances like silicon and carbon. The composition of a ceramic material affects its electrical behavior and its uses.

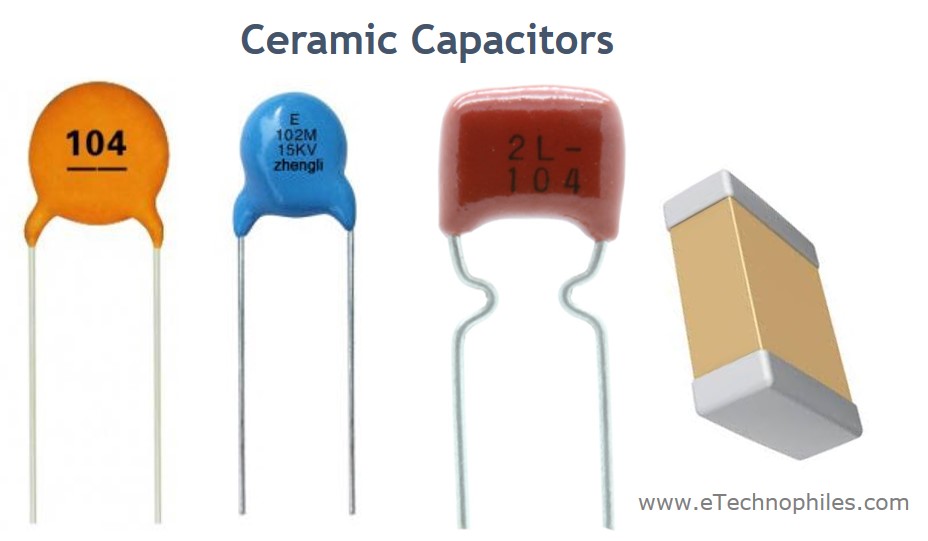

The easy-to-mold feature of ceramic material is the reason for the production of precise and larger forms of ceramic capacitors for high-voltage, high-frequency (RF), and power applications. Multilayer ceramic (MLCC) and ceramic disc capacitors are the two forms of ceramic capacitors used in modern electronics.

Are ceramic capacitors AC or DC?

If the capacitor has polarity (polarized capacitor), it is used in DC circuits. If the capacitor has no polarity (non-polarized), it can be used in both AC and DC circuits. Since a ceramic capacitor is a non-polarized capacitor, it can be easily used in AC circuits.

Ceramic capacitors are produced with a capacitance ranging from 10pF to 100F with DC operating voltages ranging from 10 volts to 5000 volts.

Applications

- To reduce RF noise. These capacitors are connected in parallel with a DC motor to reduce interference and noise.

- They are used as bypass capacitors, in op-amp circuits and filters, etc.

- Used in frequency discrimination (decoupling) or bypass applications where Q factor and stability are not important concerns.

The important applications of Ceramic capacitors are explained below:

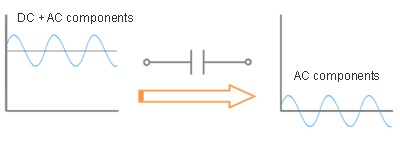

Coupling Capacitor

In a coupling circuit, a ceramic capacitor transmits only the AC signal and not the DC signal. It extracts the AC component from the AC+DC component.

In simple words, the capacitor allows AC signals to pass from one circuit to the other while blocking DC signals. Coupling capacitors are often used to connect a signal source, such as a microphone or an audio amplifier, to a load, such as a speaker or an oscilloscope.

By doing this, the capacitor prevents any DC offset voltage that may be present in the signal source from being applied to the load.

Decoupling Capacitor

A ceramic capacitor, when used as a decoupling capacitor, bypass AC signals around an electrical circuit. This is done by connecting the capacitor between the power supply and the ground, which effectively couples the AC signals together while allowing the DC signal to flow uninterrupted.

The capacitor acts as a filter, allowing only the DC signal to pass while blocking the AC signals. This process is known as decoupling, and it helps to reduce noise and improve the quality of the power supply.

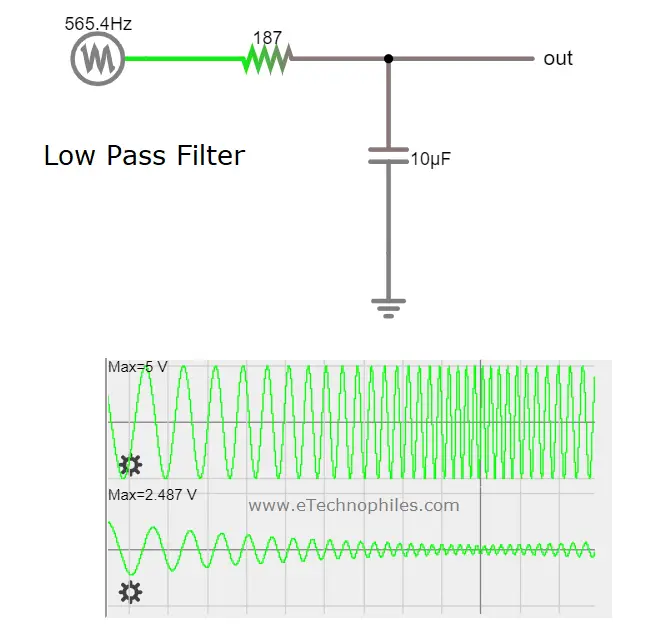

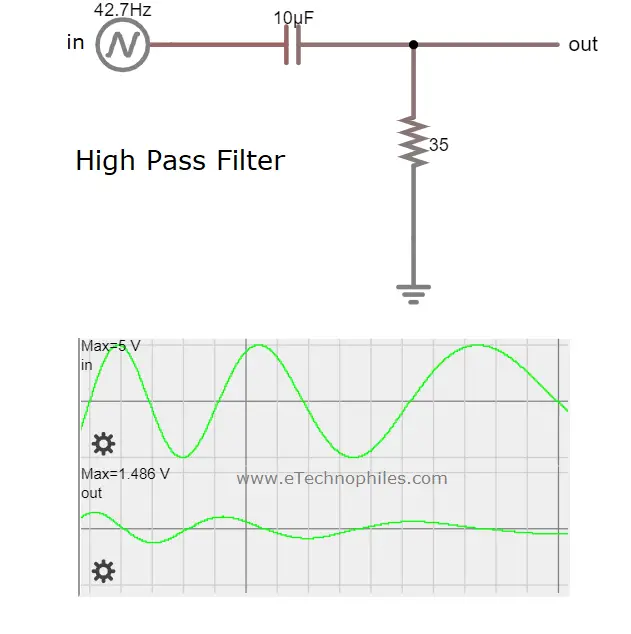

- High pass and Low pass Filter

Capacitors help in transmitting signals of a particular frequency.ie low-pass filters that filter out low-frequency components and high-pass filters that filter out high-frequency components.

Characteristics of a ceramic capacitor

The capacitor that uses ceramic material such as paraelectric like titanium oxide (with additives like Magnesium, Tantalum, Zinc, and Zirconium) or ferroelectric like barium titanate (with additives like Aluminium oxide, Magnesium silicate, and Aluminium silicate) as the dielectric is known as the Ceramic Capacitors.

The permittivity of the capacitor is determined by these added additives.

The capacitor with paraelectric material and its additives will have

- low permittivity

- linear behavior over temperature changes

- stable

The capacitor with ferroelectric material and its additives will have

- High permittivity

Ceramic capacitors have a high value of k (dielectric constant) which allows them to achieve a high capacitance value in a small physical size.

Ceramic capacitors are available in various styles and shapes. Some of them are listed below:

Types

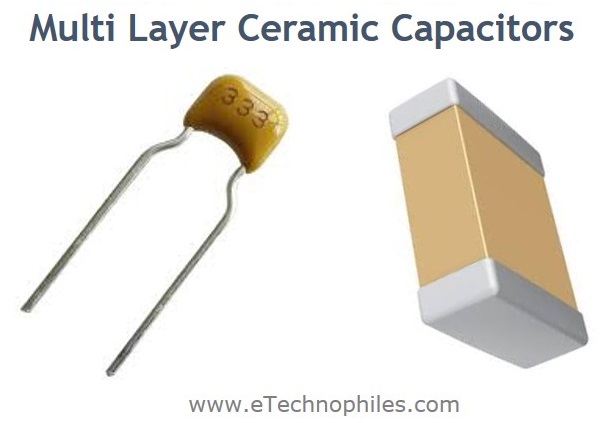

Multilayer Ceramic Chip Capacitor (MLCC): It is created by stacking a number of individual capacitors one after the other via a terminal surface. The material used is paraelectric with pre-determined additives.

The capacitance value is determined by the number of capacitors and their size. It is rectangular in shape and used for surface mounting purposes.

Disc capacitors: These capacitors are created by coating two sides of small porcelain or ceramic disc with silver and then stacking the discs together. It has through-hole leads.

A single ceramic disc of 3-6 mm can be used for low capacitance values. It has voltage ratings up to 750 V D.C. and 350V concerning A.C

Feedthrough Ceramic Capacitor (FCC): It is a three-terminal capacitor that resembles a tube. It is made with external metallization for soldiering and an inner metallization that is in contact with a lead.

FC capacitors reduce high frequencies and can be used as a by-pass capacitor.

Ceramic Power Capacitor (CPC): These types of capacitors have a larger ceramic body. They are used in high voltage power systems, electrical transformers, and various electrical installations. They have higher power ratings of more than 200 volt-amps.

Selecting the right ceramic capacitor

The ceramic capacitors’ dielectric classes can help you choose the right one for your application.

Different Dielectric Classes:

| Class | Description | Common types |

| Class 1 | Highly stable with respect to temperature change, voltage, and frequency. Exhibit low loss. Used in resonant circuits, filters, and oscillators. | NP0, P100, N33, N75 |

| Class 2 | They possess a non-linear temperature coefficient. Offers high volumetric efficiency. Used in coupling, decoupling, smoothing, and by-passing applications. | X7R, X5R, Y5V, Z5U |

| Class 3 | They offer high volumetric efficiency than class 2 capacitors. They have a permittivity value in the range of 50,000 times greater than the class 2 capacitors. Their temperature stability is not so good. | Only leaded components are available. not yet standardized. |

The International Electrotechnical Commission (IEC) and the Electronic Industries Alliance (EIA) are two international organizations that have standardized these ceramic capacitor classes.

How do these capacitors get damaged?

There are multiple ways that ceramic capacitors can malfunction and some are:

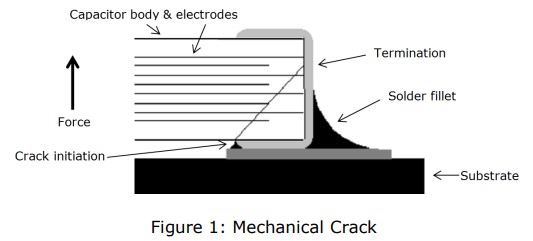

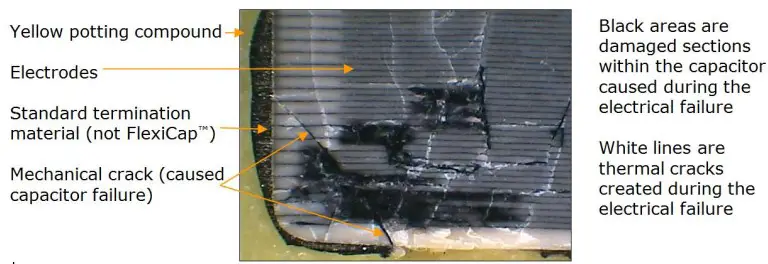

1. Cracking of Ceramic Capacitor:

Ceramic capacitors may undergo mechanical cracks due to too much physical stress i.e., bending of the board or pressure on the part. This excessive bending can develop short circuits between layers. Depending on the amount of current available from the power supply, it will either explode or simply sit there and overheat.

2. Overvoltage

Overvoltage is the second possible cause of ceramic capacitor failure. The dielectric (insulating) layers may burst under excessive voltage, creating short circuits. Excessive voltage might cause the capacitor to flex and result in a stress crack.

Ceramic vs electrolytic capacitor

| Ceramic capacitor | Electrolytic capacitor |

| Ceramics are used to separate the conductive surfaces. | Metal oxide layers and an electrolyte are used to separate the conductive surfaces. |

| The dielectric is made of ceramic material. | The dielectric consists of a very thin oxide layer. |

| Non-polarized capacitor | Polarized capacitor |

| They have a low ESR (Equivalent series resistance) value | They have higher ESR and are more strongly dependent on the frequency. |

| They exhibit microphony | They do not exhibit microphony |

Note : Microphony is an effect in which electrical noise in circuits is produced by mechanical vibrations.

FAQs

What is a ceramic capacitor used for?

They are used for decoupling, coupling, timing, tuning, and snubber applications in electronic circuits.

Which side of a ceramic capacitor is positive?

Ceramic capacitors are non-polarized components, meaning they do not have a positive or negative side. They can be connected in any orientation within a circuit.

Do ceramic capacitors have ESR?

Yes, they do have Equivalent Series Resistance (ESR), although typically it is very low compared to other types of capacitors like electrolytic capacitors.