Last updated on March 28th, 2024 at 11:39 am

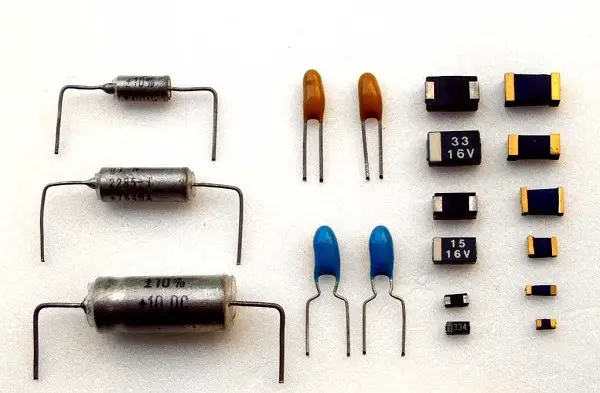

Tantalum capacitors are a type of polarized electrolytic capacitor. It uses a tantalum metal as the anode (+), a Manganese dioxide (MnO2) electrolyte as the cathode (-), and a thin coating of tantalum oxide acting as the dielectric. In this blog post, we will discuss its characteristics, uses, and failure reasons.

Table of Contents

Tantalum (Ta) is a silver-gray metal with the atomic number 73.

They have excellent frequency characteristics as well as long-term stability. Due to their infinite shelf life, high capacitance, and reliability, they are used in circuits for electronic devices like computers, cars, cell phones, and other devices. One of their drawbacks is the ‘unfavorable failure mode’ which results in thermal runaways.

Practical parameters

| Dielectric | Tantalum pentoxide |

| Working Voltage | 2.5 to 50V |

| Capacitance | 0.47 to 1000µF |

Construction

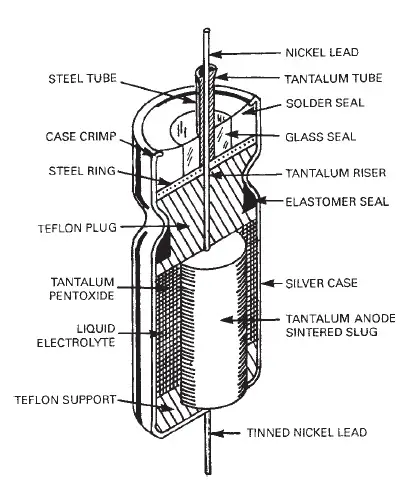

The capacitor is made of two metal plates (anode and cathode) separated by an insulating material called the dielectric. One of the metal plates is coated with a layer of oxide, which acts as the dielectric. The other metal plate is coated with a layer of tantalum metal.

When an electric potential difference is applied across the plates, an electric field develops across the dielectric, storing electrical energy in the form of charge separation. The capacitor can then release this stored energy when needed, providing a power boost to circuits.

Characteristics

- It uses tantalum powder with small particles to create a very thin dielectric layer which provides a high permittivity resulting in higher volumetric efficiency.

- It possesses a wide operating temperature of -50 to 100 degrees Celsius.

- They exhibit long-term stability with high insulation resistance and low leakage current.

- They operate above 50kHZ. As frequency increases, it experiences a small decrease in capacity. (At 10kHZ its capacity drops by less than 20%)

Note: Normally it is a polarized capacitor. To make it non-polarized or bipolar, two tantalum capacitors are connected in series and their anodes are oriented in the opposite direction.

Why do tantalum capacitors fail?

The unfavorable failure mode is one of their major drawbacks. According to ASM International’s paper, the failure modes are classified into three major categories, i.e., high leakage current, low capacitance and high ESR.

High leakage current

When a capacitor is subjected to a high leakage current, it gets damaged. This is because the current passing through it causes heating of the dielectric material, which in turn causes further leakage current and more heating. The process continues until the dielectric material is completely degraded, at which point the capacitor will fail.

To avoid this type of damage, it is important to be aware of the potential for high leakage currents. If they are not properly taken care of, they can be easily damaged.

Low capacitance

The low capacitance can damage them in two ways.

- First, it can cause an increase in equivalent series resistance (ESR). This happens because the reactance of the capacitor decreases as the capacitance decreases. When the reactance decreases, the current through the capacitor increases. The increased current causes an increase in IR drop across the dielectric, and this increases ESR.

- Second, low capacitance can cause an increase in the likelihood of a dielectric breakdown. This is because the electric field across the dielectric increases as capacitance decreases. When the electric field across the dielectric increases, it causes a higher probability of dielectric breakdown.

High ESR (equivalent series resistance)

As discussed above, high ESR may damage them. To prevent this from happening, it is important to choose a tantalum capacitor with low ESR. You can also use a heatsink to help dissipate heat and protect them from damage.

To avoid failure actions, external failsafe circuitry such as current limiters and thermal fuses should be used in combination with tantalum capacitors.

Applications

They are used in a variety of applications, particularly in modern electronics for higher stability to withstand a wide range of temperatures and frequencies, long-term reliability, and record-high volumetric efficiency. These include:

- Sample and hold circuits: Low leakage current helps in long hold duration.

- Military applications: as they do not dry out and change capacitance frequently

- Life-sustaining medical devices (cardio implants): They can detect irregular heartbeats and quickly deliver an electric countershock.

- Surface mount tantalum capacitors are used for power supply filtering in computer motherboards and cell phones due to their long-term stability and small size.

- Tantalum electrolytic capacitors are suitable for storing electrical energy and also for passing or bypassing low-frequency signals due to their large capacitance.

- Audio circuits: They are used in audio circuits, due to their capacity to reduce the loss of small currents for high-frequency audio, which improves the sound quality.

What is the difference between tantalum and ceramic capacitors?

Tantalum and ceramic capacitors serve similar purposes, but they are made using different materials and perform very differently. When it comes to performance, there are a few key differences between them.

| Parameter | Tantalum Capacitor | Ceramic Capacitor |

| Aging | Do not age | They age with time |

| Type | They are polarized. So they can be connected to a DC power source by maintaining proper polarity | They are non-polarized. So it can be connected to an AC source and have a higher frequency response |

| Temperature coefficient | They have a linear temperature coefficient | They have a non-linear temperature coefficient |

| Capacitance variation | The capacitance changes for the applied voltage | The capacitance changes concerning the applied voltage |

FAQs

Why are tantalum capacitors so expensive?

Tantalum material is fairly a rare metal and it needs large mining which leads to high prices of tantalum capacitors.

What is the difference between tantalum and normal capacitors?

Tantalum capacitors use tantalum metal and solid manganese dioxide electrolyte, providing high capacitance in a compact size. Normal electrolytic capacitors, often aluminum-based with liquid electrolyte, offer a wider range of capacitance. Tantalum capacitors are polarized, unlike some electrolytic capacitors.

What is the best replacement for tantalum capacitors?

Aluminum electrolytic or polymer capacitors are common replacements for tantalum capacitors. Ceramic capacitors may be suitable for high-frequency applications. Consider size, performance, and cost when choosing a replacement.