Last updated on March 16th, 2024 at 01:50 pm

An electrical fuse is a type of safety device that protects a circuit from overcurrent conditions. It is connected in series with the electrical load. It contains a wire or metal strip enclosed inside a housing. The metal wire or strip melts when the circuit’s current exceeds a specified threshold, cutting off the flow and protecting the circuit from harm.

Fuses are frequently employed in industrial and domestic electrical systems to prevent dangers like electrical fires. Depending on the particular use, they come in a range of sorts and ratings.

Table of Contents

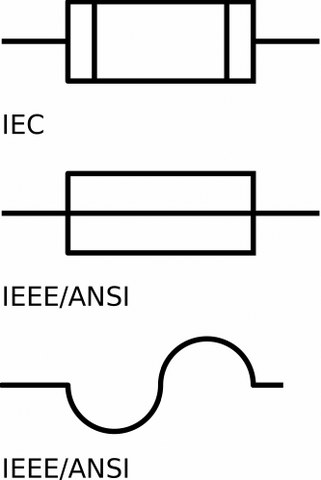

Electrical fuse symbol & working

In any electrical circuit, fuses are represented by the symbols shown in the figure below.

A fuse works by interrupting the flow of current in an electrical circuit when the current exceeds a predetermined level.

The fuse consists of a metal wire or filament that is connected between two metal end caps. When an excessive amount of current flows through the fuse, the heat generated by the current causes the metal wire or filament to melt. This melting of the fuse breaks the electrical circuit and stops the flow of current, thus preventing damage to the electrical system.

Note: When a fuse gets blown, it is important to replace it with a new fuse of the same type and rating. This ensures that the new fuse can provide the same level of protection as the old one. If a fuse is replaced with a fuse of a higher rating, it may not provide adequate protection against overloading or short circuits.

Depending on the individual application and desired level of protection, fuses come in a range of forms and ratings.

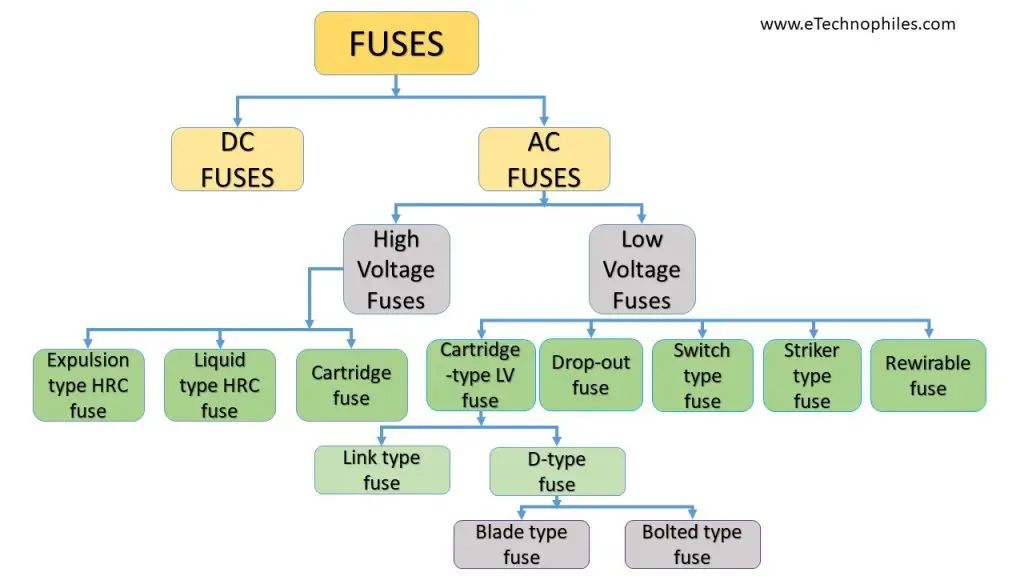

Classification of fuses

Fuses are divided into two types, i.e., DC and AC Fuses. AC fuses are further divided into two parts one is high-voltage fuses which we use for high-voltage applications and the other is low-voltage fuses which get used for low-voltage applications.

High voltage fuses are of three types: Expulsion-type HRC fuse, Liquid-type HRC fuse, and Cartridge Fuse. Low voltage fuses are classified into five types: Cartridge-type LV fuses, Drop-out fuses, Switch-type fuses, Striker-type fuses, and Rewirable fuses.

Expulsion type HRC fuse

An expulsion-type HRC fuse consists of a metal casing filled with a low-melting-point alloy that acts as the interrupting element. When the current passing through the fuse exceeds the rated limit, the heat generated causes the alloy to melt and vaporize, creating a gap in the circuit that interrupts the flow of current. This interruption occurs quickly and prevents further damage to the electrical circuit.

The metal casing of the fuse is designed to contain the vaporized metal and prevent it from spreading to the surrounding area.

The expulsion-type HRC fuse is known for its high performance, reliability, and durability, making it a popular choice for various industrial and commercial applications.

Liquid-type HRC fuse

A liquid-type HRC (High Rupturing Capacity) fuse is a type of electrical fuse that uses a liquid medium to extinguish an electrical arc. This type of fuse is typically used in high-voltage electrical power systems to protect against short circuits and overcurrents.

When the current exceeds the fuse’s rated current, the liquid medium (usually oil or silicone) is vaporized by the heat of the arc, creating a gas that extinguishes the arc and interrupts the current flow.

Liquid-type HRC fuses are known for their high breaking capacity and stability, but it is not as common as solid-state or air-type HRC fuses.

Cartridge fuse (HV)

The fuse typically has a cylindrical shape and the fuse element (usually made of silver) is enclosed in a tube made of ceramic or glass material. The fuse element is connected to end caps, which are in turn connected to the electrical circuit. When an overcurrent or short circuit occurs, the fuse element melts, breaking the circuit and protecting the electrical equipment from damage.

Cartridge high-voltage AC fuses are used in a wide variety of practical applications, such as power distribution systems, industrial plants, power substations, commercial buildings, and residential properties.

Note: These fuses are used in high-voltage and power systems, hence, safety is a prime concern. The installation, operation, and maintenance of cartridge fuses should be done by qualified electricians and maintain the safety standard.

Cartridge-type LV fuse

Low-voltage (LV) cartridge fuses are a specific kind of electrical fuse that is used in low-voltage electrical power systems. These fuses come in AC and DC varieties and operate at voltages lower than 600 volts.

They are typically cylindrical in shape and the fuse element (often an alloy of metals) is contained in a glass or ceramic tube. End caps are coupled with the fuse element. The fuse element melts in the occurrence of an overcurrent or short circuit, interrupting the circuit and protecting the electrical equipment from harm.

They are widely utilized in numerous applications, including lighting and appliance circuits, motor control and feeder protection, and branch circuit protection.

LV fuses are generally smaller in size and cost less than high-voltage fuses. They are also relatively easy to install and maintain, which makes them a popular choice for electrical protection in low-voltage power systems.

Cartridge fuses are further divided into the two categories below:

- ‘D’ Type Fuses

- Link Type Fuse

‘D’ Type Fuse

A D-type fuse consists of a metal casing that contains the interrupting element (fuse link). D-type fuses are a popular option for LV electrical protection in residential, commercial, and industrial applications because of their simplicity, dependability, and affordability.

Link Type Fuse

A link-type fuse consists of a metal wire or filament that is connected between two metal end caps. Link-type fuses come in a variety of sizes and ratings and are frequently used in applications like power distribution, motor control, and lighting. Because they are straightforward to install and replace, they are a well-liked choice for electrical protection.

Drop-out fuse

It is called a “drop out” fuse because when the fuse element melts and opens the circuit, the fuse link drops out of the holder, indicating that the fuse needs to be replaced. These fuses are typically used in residential and commercial electrical systems to protect against damage from short circuits and other overcurrent conditions.

Read also: Induction Motor: Construction, Working principle & Advantages

Switch-type fuse

These fuses are different from “drop out” fuses as they are equipped with a switch mechanism, which allows the user to manually open or close the circuit. This allows for easy isolation of the circuit for maintenance or troubleshooting without having to remove the fuse from the holder.

These fuses are typically used in industrial and commercial electrical systems, where the ability to manually open or close the circuit is necessary for safe and efficient maintenance and troubleshooting.

Striker-type fuse

A striker-type fuse consists of a metal striker that is held in place by a spring and a metal fuse element. When an excessive amount of current flows through the fuse, the heat generated by the current causes the fuse element to expand, pushing the striker out of its holder and into contact with a metal casing.

This creates a spark, which ignites a pyrotechnic charge and melts the metal fuse element, breaking the electrical circuit and stopping the flow of current. Applications like automotive electrical systems, where quick response and reliable performance are essential, typically use striker-type fuses.

Rewirable fuse

A rewirable low voltage AC fuse is a type of fuse that can be easily rewired or reconnected to the circuit after it has opened due to an overcurrent. These fuses typically have a switch mechanism that allows the user to manually open or close the circuit, and a rewirable fuse link that can be removed and replaced.

This allows for easy isolation of the circuit for maintenance or troubleshooting without having to replace the entire fuse. These fuses are typically used in industrial and commercial electrical systems, where the ability to manually open or close the circuit and easy maintenance is necessary for safe and efficient operation.

Read more on fuses.

FAQs

What is 10 red fuse?

A “10 red” fuse typically indicates a 10-ampere fuse with a red-colored housing or marking. It can carry a maximum current of 10 amps before blowing to protect the circuit.

What is the full form of PT fuse?

The full form of “PT fuse” is “Power Transformer fuse.”

What is fuse 5 marks?

A fuse marked with “5A” indicates a current rating of 5 amperes