Last updated on March 23rd, 2024 at 06:05 pm

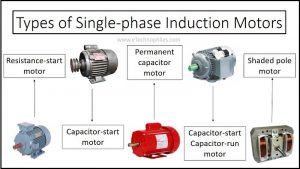

There are 5 types of single-phase induction motors on the basis of their starting methods: Resistance start, Capacitor start, Capacitor start capacitor run, Permanent Capacitor, and shaded-pole single-phase induction motor. Each of them is discussed in detail below.

A single-phase induction motor creates an alternating magnetic field on giving an AC supply to its windings. But the magnetic field generated by it is pulsating. In other words, the magnetic field does not rotate, as in the case of a three-phase induction motor.

The magnetic field builds up in one direction, falls to zero, and then builds in the opposite direction. Thus, we need some external aid to make the magnetic field rotate. By using some starting methods, we can make a single-phase induction motor self-starting.

Based on these starting methods, there are five types of single-phase induction motors. But before discussing the types of single-phase induction motors, let us see the minimum requirements to create a rotating magnetic field.

Table of Contents

How rotating magnetic field is generated in single phase Induction motor

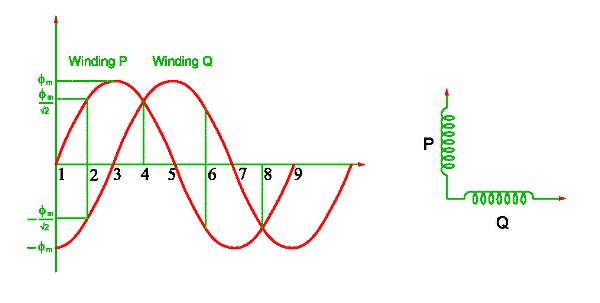

A rotating magnetic field requires at least two windings. And the setup must follow these two rules:

- The windings must be 90 electrical degrees apart.

- They must be excited by two alternating EMFs that are displaced 90 degrees in the time phase.

**Image courtesy: Electrical Revolution

But a single-phase induction motor has only one winding. So, to create a rotating magnetic field using a single AC supply and single winding, an auxiliary winding is used. This winding is placed perpendicular to the primary winding of the motor.

The impedance of the auxiliary winding is different from that of the primary winding. Thus, it creates a phase difference between the currents flowing in the two windings, which leads to the creation of a rotating magnetic field.

Types of single-phase induction motors

Based on the type of impedance connected to the auxiliary winding of the motor, there are five types of single-phase induction motors.

- Resistance start motor

- Capacitor start motor

- Capacitor start capacitor run motor

- Permanent capacitor motor

- Shaded pole motor

Let us discuss each of the above types of single-phase induction motors in detail.

Resistance-start single-phase induction motor

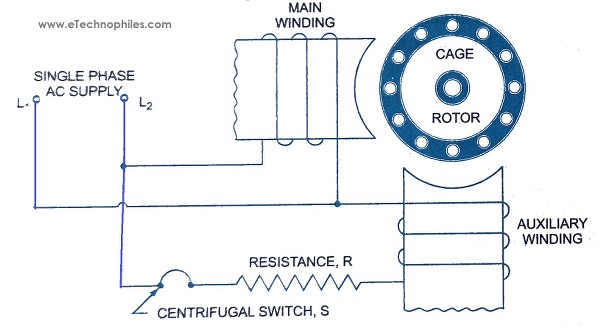

In this method, we connect a high resistance in series with the auxiliary winding of the motor, as shown in the figure.

The overall inductance in both the windings is as follows:

- The auxiliary winding has a high resistance but a low inductive reactance.

- The primary winding has a low resistance but a high inductive reactance.

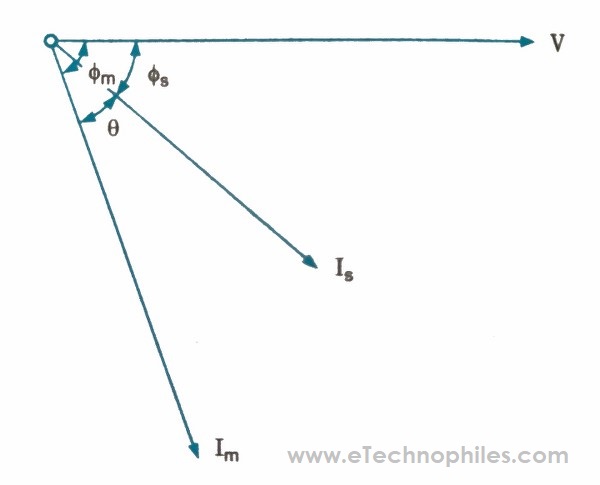

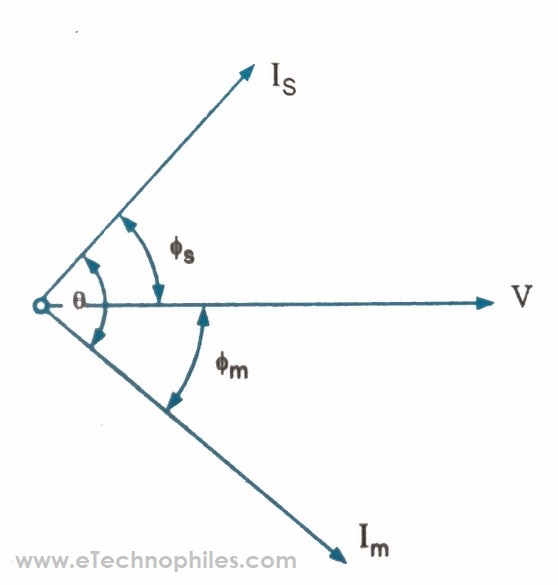

Due to this, the primary winding current (Im) lags the applied voltage by 65-75 degrees, while the auxiliary winding current (Is) lags by 35-45 degrees. Thus, there is a difference of about 20-30 degrees between both currents, as shown in the phasor diagram below.

Although there lies a small phase difference between the currents, it is still sufficient to start the motor.

As the motor speed reaches 75 to 80% of synchronous speed, a centrifugal switch disconnects the auxiliary winding from the motor circuit. It protects the auxiliary winding from overheating and burning.

Applications

- These motors are ideal only for small inertia loads that require moderate starting torque.

- It includes woodworking tools, grinders, fans, blowers, etc.

Capacitor-start single-phase induction motor

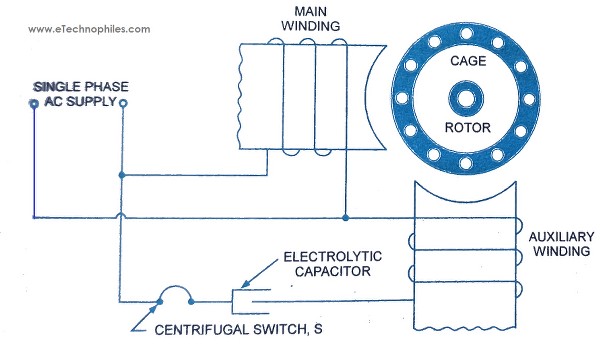

It is an improved form of the resistance-start method. It contains an electrolytic capacitor in series with the auxiliary winding. In this case:

- The auxiliary winding has a higher capacitive reactance.

- The primary winding has a high inductive reactance.

Due to this, the current in the primary winding lags the applied voltage, while the auxiliary winding current leads the applied voltage, as shown in the phasor diagram.

It is visible that the phase difference between the currents has increased significantly. Hence the starting torque of the motor also increases.

Applications

- Capacitor start motors are efficient to use in fans, blowers, jet pumps, sump pumps, etc.

- They are also ideal for farm and home workshop tools, oil burners, etc.

Capacitor-start, capacitor-run single-phase induction motor

Although the use of an electrolytic capacitor increases the starting torque, it has two problems:

- These capacitors are rated only for short-duty service. It gets damaged if used for a longer time.

- The dielectric of the capacitor gets damaged if the motor is started too frequently in a short time interval.

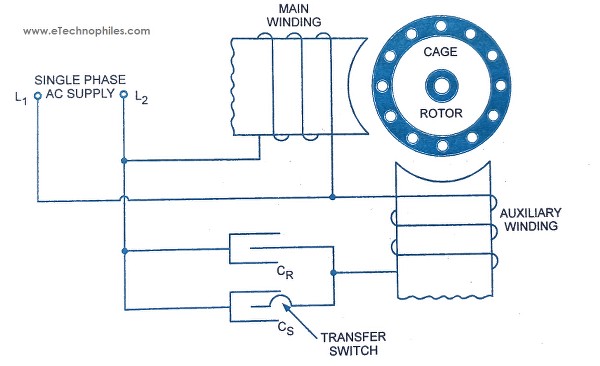

So, to get smooth starting and running conditions, we use capacitor-start, capacitor-run motors. It uses two different capacitors placed parallel to each other, as shown in the figure.

- The first one is an oil-impregnated capacitor (Cr). It is a continuous rating capacitor with a smaller value.

- The second one is an electrolytic capacitor (Cs). It is a short-duty capacitor with a higher value.

During starting, both the capacitors remain in the circuit. The overall capacitance gets added, which gives a higher starting torque.

When the motor picks 75% of the synchronous speed, the centrifugal switch disconnects the starting capacitor (Cs) from the circuit. Thus after that, only the running capacitor (Cr) remains with the auxiliary winding.

This method is different from the above two types of single-phase induction motors. Here, the auxiliary winding remains connected in the circuit at all times, i.e., both starting and running.

Advantages

- It produces a constant torque and generates less noise.

- These motors have a 25% better overload capacity.

- Its efficiency is better than the above two types of single-phase induction motors.

Applications

- Due to a better starting and running torque, these motors are ideal for compressors, refrigerators, and pumps.

- Their low noise feature makes them beneficial to use in hospitals and studios.

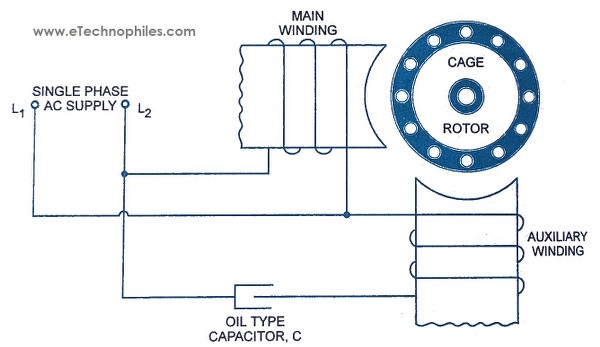

Permanent capacitor single-phase induction motor

This motor uses only one capacitor in series with the auxiliary winding. Here, the capacitor remains connected in the circuit during the starting as well as running. So, there is no need for a centrifugal switch, as discussed in the above types of single-phase induction motors.

The advantages of this motor are similar to that of a capacitor start, capacitor run induction motor. But due to the use of only one capacitor, this motor can’t give optimum starting and running conditions. It uses a Pyranol-insulated foil paper capacitor.

Applications

- They are ideal for ceiling fans, blowers, room coolers, and other domestic applications.

- Due to the simple reversal of the motor, they are best for induction regulators and furnace controls.

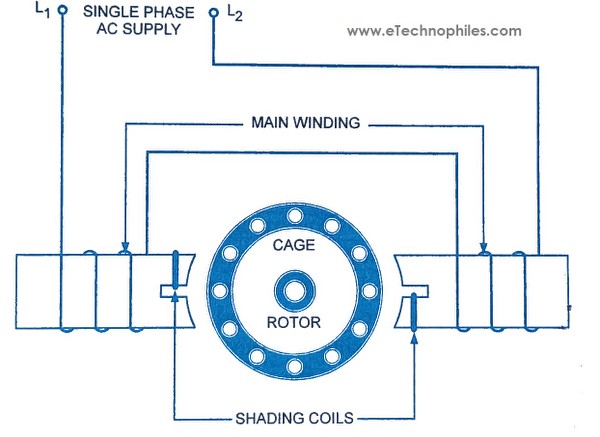

Shaded pole motor

This motor is entirely different from the above types of single-phase induction motor. It does not have any capacitors or moving switch parts. Its stator has salient poles, provided with its exciting coil. A copper strap (shading coil) wraps around 25% of the stator pole, as shown in the figure.

Working

A single-phase supply to the stator coil sets an alternating magnetic field in the core. This alternating magnetic field interacts with the shading coil and induces a current in the shading coil. The shading coil current creates a flux (shading coil flux), which lags the main coil flux by some angle.

It appears that field flux shifts from the unshaded portion to the shaded part of the pole. This shifting of flux is like a weak rotating field. This rotating field interacts with the rotor and creates a starting torque.

Applications

- Due to low starting torque, they are only suitable for toys, small fans, electric clocks, etc.

- They are also ideal for small business machines like photocopying and vending machine.

Very clear & well presented. Thank you

Well explained. Thanks

Thank you for the explanation, The drawings Well explain it

Well explained. Thanks a lot!