Last updated on March 26th, 2024 at 04:03 pm

An AC motor is simply an electromechanical circuit that converts electrical energy to mechanical energy. This mechanical energy is either utilized in industrial or domestic applications. Based on the operating principle, we can classify AC motors into two types. i.e., Induction and Synchronous Motors. If these names are unfamiliar to you, don’t worry and stick with this article to learn the difference between Induction and Synchronous motor.

Key differences between Induction Motor and Synchronous Motor

The table below gives a quick difference between an induction motor and a Synchronous motor.

| SYNCHRONOUS MOTOR | INDUCTION MOTOR |

| It is a doubly excited machine. | It is a singly excited machine. |

| Both AC and DC supplies are required to start a Synchronous motor. | Only an AC supply is sufficient to start an Induction motor. |

| The stator of the motor is energized from an AC supply while the rotor is energized from a DC supply. | Here, only the stator is energized from an AC supply. |

| The motor always runs at synchronous speed. | The motor always runs at a speed less than synchronous speed. |

| It works on the principle of magnetic locking. | It works on the principle of electromagnetic induction. |

| The speed of the motor is independent of load. | The speed of the motor depends on the load. As the load increases, the speed of the motor decreases. |

| It is not self-starting. | It is a self-starting motor. |

| No relative motion between stator and rotor is required to operate the motor. | A relative motion between a stator and rotor is necessary to operate the motor. |

| A Synchronous motor can be operated either at unity, lagging, and leading power factor. | An Induction motor operates only at a lagging power factor. |

| Synchronous motor can also be used for power factor correction apart from supplying mechanical loads. | The induction motor is used to drive mechanical loads only. |

| For the same output and voltage rating, a synchronous motor is more efficient. | Its efficiency is less as compared to the synchronous motor for the same output and voltage rating. |

| For the same specifications, a synchronous motor is costlier than an induction motor. | An induction motor is cheaper than a Synchronous motor. |

Table of Contents

Let us learn about both of these motors, starting with some basic terminologies of AC motors.

Basic terminologies of AC motors

- Stator: A stator is a stationary part of a machine. It provides mechanical support and also protects the motor from the outside environment. The windings on its inner periphery create a rotating magnetic field on giving an AC supply to them.

- Rotor: A rotor is the rotating part of the motor. It is a crucial portion where the electromechanical energy conversion occurs.

- Synchronous speed: It is the speed with which the rotating magnetic field of the stator rotates. The synchronous speed always remains constant. It only depends on the frequency of AC supply and the number of stator poles. By using a simple formula, we can determine the synchronous speed (N) of a motor. If we denote the supply frequency by (f) and stator poles by (p), then the synchronous speed (N) is N = (120*f)/p. Now, if a motor has four poles and the frequency of incoming AC supply is 50Hz, then substituting these values in the above formula N = (120*50)/4 gives 1500. So, the synchronous speed of this motor is 1500RPM.

**If you want to know how an AC motor works, read a detailed article here, Working of AC Motor.

So, let us start our discussion on AC motors with a Synchronous Motor.

Synchronous motor

A motor whose rotor rotates with synchronous speed is known as a synchronous motor. So, in synchronous motors, both the rotating magnetic field and the rotor rotates at synchronous speed. Even a change in the mechanical load connected to this motor does not alter the speed of the motor. In other words, the speed of the motor always remains constant. But, now a question arises, how does this happen?

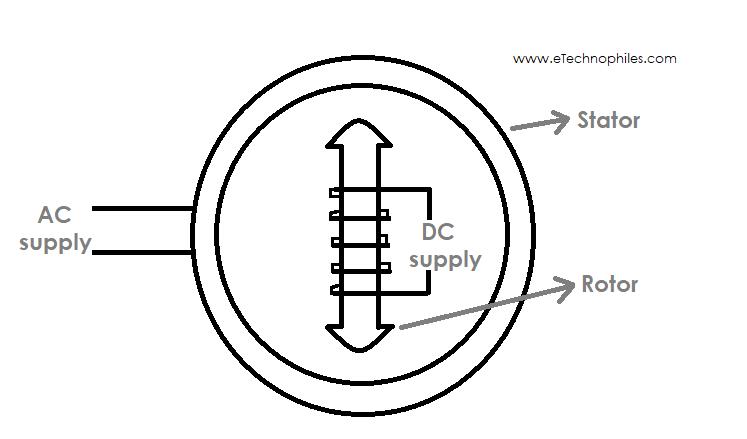

Excitation of synchronous motor

The armature winding covers the entire inner periphery of the stator while the rotor contains the field winding. For a constant-speed operation, this motor requires two sources of supply: an AC source to energize the armature winding and a DC source to excite the field winding. Hence, it is also known as a doubly excited machine.

Working of synchronous motor

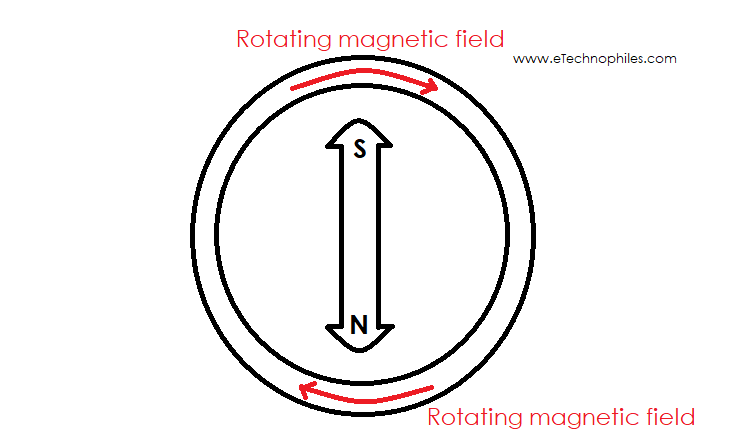

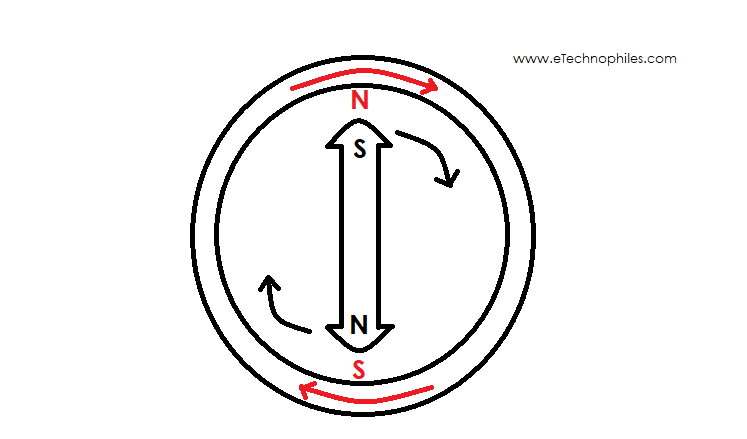

The synchronous motor works on the principle of magnetic attraction. As soon as the stator gets an AC supply, a rotating magnetic field develops in the air gap of the motor. Exciting the rotor with a DC supply creates an electromagnet with a fixed polarity, as shown in the figure.

Now consider an instant when the North pole of the rotating magnetic field comes over the South pole of the electromagnet, as shown in the figure.

So an attractive force develops between the unlike poles of the stator and the rotor. Now, as the stator magnetic field is rotating at a synchronous speed, it will pull the rotor poles along with it.

As a consequence, the rotor starts rotating in synchronism with the rotating magnetic field. And hence, the rotor always runs at synchronous speed.

Applications

- Factories, powerhouses, and substations require a synchronous motor to improve the power factor.

- They are used to regulate the voltage level at the end of transmission lines.

- Synchronous motors are a perfect choice for constant-speed loads. It includes fans, blowers, compressors, reciprocating pumps, rubber, and paper mills.

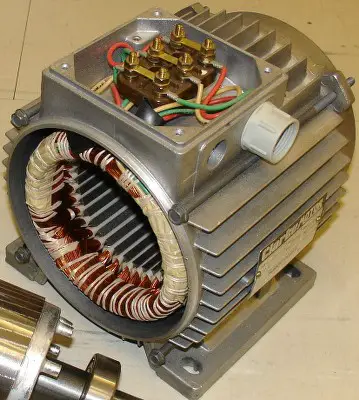

Induction motor

The rotor of an induction motor runs at a speed other than synchronous speed. In other words, there lies a relative motion between the rotating magnetic field and the rotor. That’s why this motor is also known as an asynchronous motor. The speed of an induction motor reduces as the mechanical load on it increases. So, what is the main difference between an induction motor and a synchronous motor?

**Image courtesy: Wikipedia

Excitation of Induction Motor

The stator contains slots for a uniformly distributed field winding in an induction motor while the rotor carries the armature winding. The difference between the excitation of the induction motor and the synchronous motor is that the induction motor is a singly excited machine. It means that only a single source is enough for its operation.

Working of Induction Motor

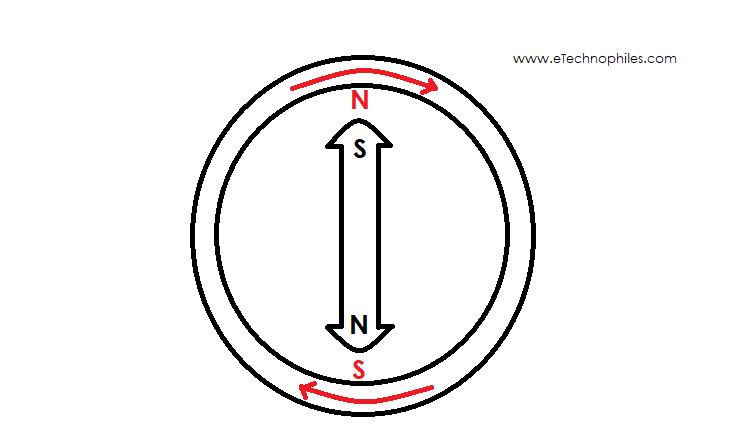

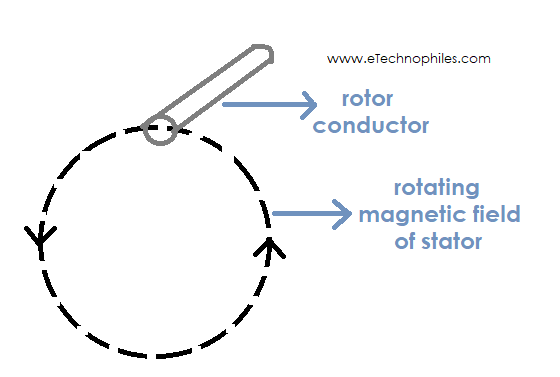

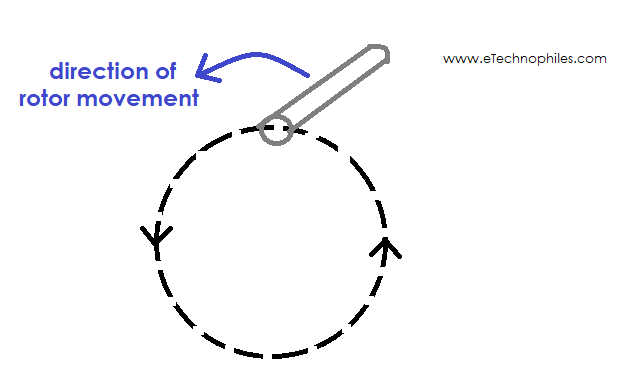

As the stator gets an AC supply, the induction motor also creates a rotating magnetic field in the motor’s air gap. While rotating, these magnetic field lines interact with the rotor conductors, as shown in the figure.

According to Faraday’s law, the rate of change of the magnetic field induces a voltage in these conductors. As the rotor conductors form a closed path, the circuit gets completed, and a current starts flowing in the rotor conductor.

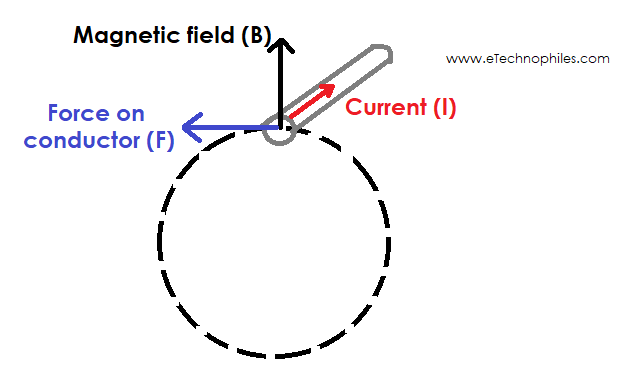

According to Lorentz law, a force acts on the conductor, as shown in the figure.

The generated force acts orthogonally to both the direction of the magnetic field and the direction of current flow. It makes the rotor move with the rotating magnetic field.

In an induction motor, the rotor rotates at a slower speed as compared to synchronous speed. i.e., there always lies a relative motion between the rotating magnetic field and the rotor.

Applications

- The induction motors are ideal for high torque applications.

- The induction motor is efficient in running domestic appliances, viz., pumps, small fans, mixers, toys, drilling machines, etc.

- Induction motors meet almost more than 90% of industrial mechanical power requirements.

Read similar articles:

|DC Motor Working Principle, Construction and Diagram Explanation

|DC Generator Working Principle, Construction and Diagram Explanation