Last updated on March 26th, 2024 at 11:34 am

A Synchronous motor is a type of AC motor that runs at a constant speed, known as synchronous speed. The rotor in a synchronous motor always maintains synchronism with the rotating magnetic field of the stator.

Even the load variations do not alter the motor’s synchronism. Hence, synchronous motors are used in constant-speed applications. But, have you ever wondered how does a synchronous motor work and give a constant speed? If not, then keep on reading this article to know everything about synchronous motors.

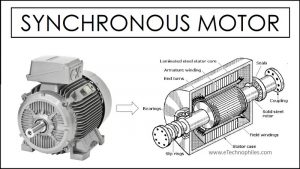

Construction of a Synchronous motor

The essential parts of a three-phase synchronous motor are:

Stator

It is a stationary part of the machine that carries the armature winding. A three-phase supply to the stator winding creates a rotating magnetic field in the air gap between the stator and rotor.

Rotor

It is the rotating part of the machine and carries the field winding. The field winding requires a DC source for its excitation. After excitation, the rotor becomes a permanent magnet and interacts with the stator field.

So, to run a synchronous motor, two sources of excitation are required. Hence, synchronous motors are also known as the doubly-excited machine.

Synchronous motor working principle

Magnetic poles of the same polarity repel each other while the magnetic poles with opposite polarity attract. This law of magnetic attraction is the principle behind the working of synchronous motors. Let us understand the application of this principle in detail.

Working of synchronous motors

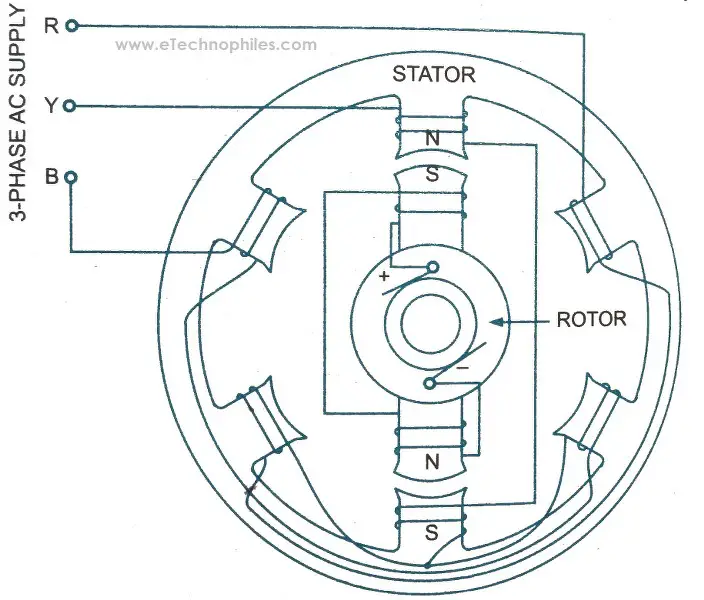

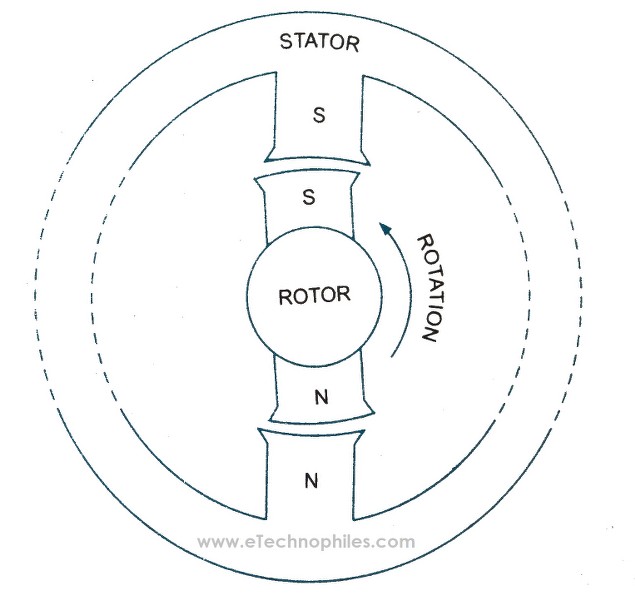

Assume a salient pole rotor inside the stator periphery. When we give a three-phase supply to the stator, it creates a rotating magnetic field in the air gap between the stator and the rotor.

On exciting the rotor windings with a DC supply, the rotor becomes a permanent magnet with fixed polarity, as shown in the figure.

Assume the rotor is stationary and in the position as shown in the figure.

Case 1:

At this instant, the North pole of the stator attracts the rotor’s South pole, and the rotor tends to move in a clockwise direction (because the stator field is rotating in the clockwise direction).

Case 2:

But after a half cycle, the polarity of stator poles gets reversed (due to the nature of AC supply). However the polarity of the rotor remains the same (because it is excited by the DC supply). So, now the magnetic poles of the same polarity face each other, as shown in the figure.

As the same type of poles repels each other, the South pole of the stator repels the rotor’s South pole, and the rotor tends to rotate in the counter-clockwise direction.

After another half cycle, the situation becomes similar to case 1, and case 2 follows up in the next half-cycle.

So, we conclude that the torque acting on the rotor of the synchronous motor is not unidirectional. It experiences a pulsating torque, due to which the rotor does not rotate in any direction. So, now the question arises, how to make the rotor move and start the motor?

Starting methods of synchronous motor

So, we saw that even after giving the rotor a proper DC supply, it pulsates about its axis. Or we can say, the synchronous motors are not self-starting. So, breaking the inertia of rest requires additional help. It can either be achieved by:

- Using an external prime mover

- Using damper windings in the rotor

First, let us see how an external prime mover makes the rotor move.

Using an external prime mover

An external prime mover first rotates the rotor of this motor at synchronous speed. Once the rotor synchronizes with the rotating field, the external prime mover is then disconnected. Now, due to magnetic locking, the motor remains in synchronism and rotates at synchronous speed.

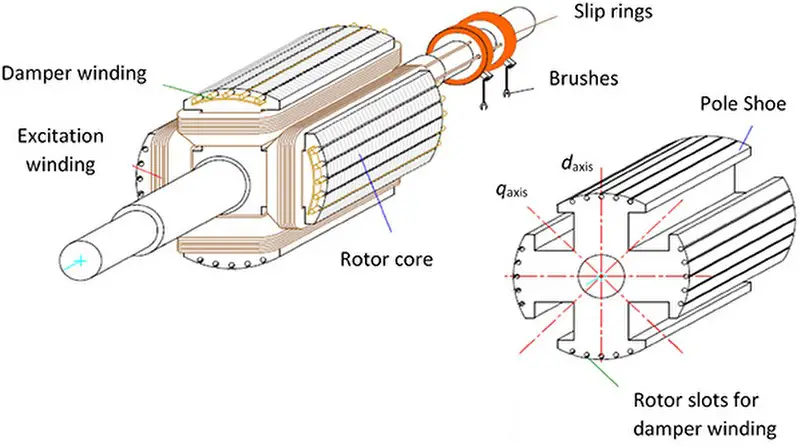

Using damper windings in the rotor

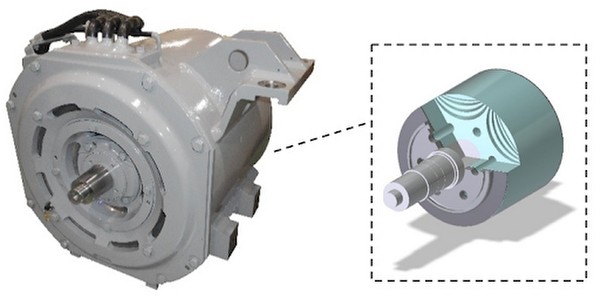

**Image courtesy: IOP Science

It is the most common method to start this type of motor. This method uses hard copper bars inside the slots of rotor poles. The end rings short the copper bars, and the arrangement looks similar to a squirrel cage winding.

So how does it rotate the rotor?

The rotating magnetic field of the stator induces a current in the damper winding. It creates a force that makes the rotor move.

So initially, the rotor starts just like an induction motor. As the rotor achieves a particular speed, the rotor windings are excited by a DC supply, and the rotor becomes a magnet.

As a result, the stator’s rotating magnetic field pulls the rotor in synchronism with it. Hence the motor starts running at a synchronous speed.

Types of synchronous motor

We can classify synchronous motors into two types based on their excitation.

- Non-excited synchronous motors

- Current-excited synchronous motors

Let us first learn about the non-excited synchronous motor.

Non-excited synchronous motor

These motors do not require a DC supply for rotor excitation. Instead, it uses a rotor made of high retentivity steel (cobalt steel).

Hence the rotor retains the magnetic properties and acts as a permanent magnet. On this basis, we can classify non-excited synchronous motors into three types.

- Hysteresis motor

- Reluctance motor

- Permanent magnet motor

Hysteresis motor

It uses a smooth cylindrical rotor made of hard cobalt steel. Due to a wide hysteresis loop of cobalt steel, the rotor initially moves with a slip. As the rotor picks speed, the stator field pulls the rotor into synchronism.

Reluctance motor

The synchronous reluctance motor uses a salient pole rotor. The figure below shows a salient pole rotor. As the rotor is not symmetrical, the reluctance of the air gap is also not uniform. The reluctance becomes minimum when the rotor aligns with the stator’s magnetic field. Hence, it creates a torque that always tries to align the rotor with the rotating magnetic field.

Permanent magnet motor

This motor uses a permanent magnet to create a constant magnetic field. The rotating magnetic field of the stator interacts with the rotor field and makes the rotor move. Due to a magnetic locking between them (stator and rotor), they remain in synchronism.

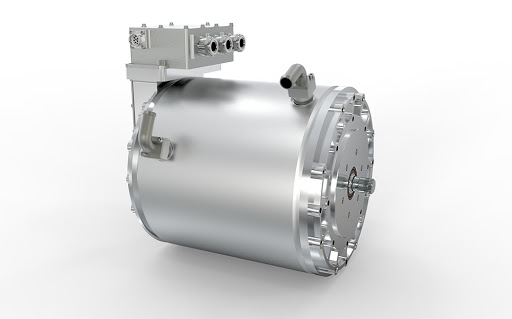

Current excited synchronous motor

It uses a DC supply to excite the rotor. After excitation, the rotor becomes a permanent magnet and creates a constant magnetic field.

These motors require a damper winding to start. So, initially, they start as an induction motor, and after attaining a synchronism run as a synchronous motor.