Last updated on March 23rd, 2024 at 01:48 pm

An induction motor is the most commonly used AC motor in homes, offices, and industries. The reasons are its low cost, rugged construction, and sufficiently high efficiency. Based on the AC power supply given to the motor, there are two types of Induction motors, viz, Single-phase and a Three-phase Induction motor. In this article, we will discuss the difference between a single-phase and a three-phase induction motor.

Difference between a single-phase and a three-phase Induction motor

The table below gives a quick comparison between a single-phase and a three-phase induction motor.

| Single-phase Induction motor | Three-phase Induction motor |

| It requires a single-phase AC source for its operation. | It requires a three-phase AC source for its operation. |

| The construction of a single-phase induction motor is simple. | The construction of a three-phase induction motor is complex. |

| This motor is not self-starting. | This is a self-starting motor. |

| A single-phase motor has two slips. A forward slip (s), and a backward slip (2-s). | A three-phase induction motor has only one slip, i.e., forward slip (s). |

| The starting torque of this motor is low. | The starting torque of this motor is high. |

| Its efficiency is less. | Its efficiency is more. |

| For the same power and voltage rating, the size of a single-phase induction motor is more as compared to a three-phase motor. | For the same power and voltage rating, the size of a three-phase induction motor is less as compared to a single-phase motor. |

| Based on starting methods, there are five types of single-phase induction motors. | Based on the rotor type, there are two types of three-phase induction motors. |

| It is easy to repair a single-phase induction motor. | It is difficult to repair a three-phase induction motor. |

| There is no practical way to change the direction of rotation. | In the case of a three-phase induction motor, it is easy to change the direction of rotation. |

| It is cheaper. | It is quite expensive. |

| The power factor of a single-phase induction motor is low. | The power factor of a three-phase induction motor is high. |

| A single-phase induction motor is suitable for domestic loads. | A three-phase induction motor is suitable for industrial and commercial loads. |

| The reliability of a single-phase induction motor is more. | The reliability of a three-phase induction motor is less. |

Table of Contents

Key differences in detail (1-Φ vs 3-Φ I.M)

The above table only gives a brief comparison between a single-phase and a three-phase induction motor. Let us break down each difference between a single-phase and a three-phase induction motor in detail.

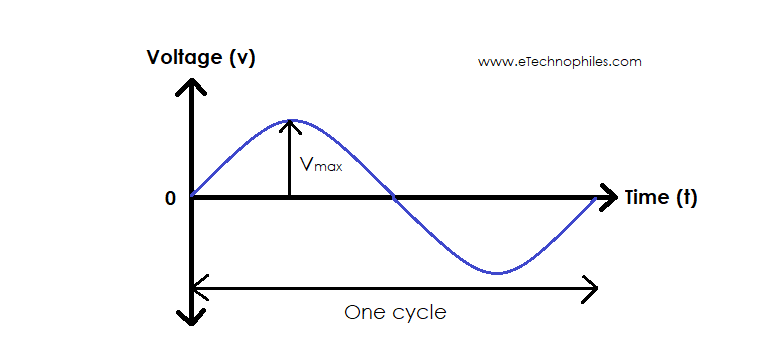

The nature of supply

In our AC electrical system, a Single-phase and a three-phase supply are the two most commonly used AC supplies. So, the motor that requires a single-phase supply for its operation is known as a single-phase induction motor. And the one that makes use of a three-phase AC supply for its operation is a three-phase induction motor.

Construction features

Due to only a single source of AC supply, the construction of a single-phase induction motor is simple. However due to the three-phase source requirement, a three-phase induction motor construction is more complex.

Starting behavior

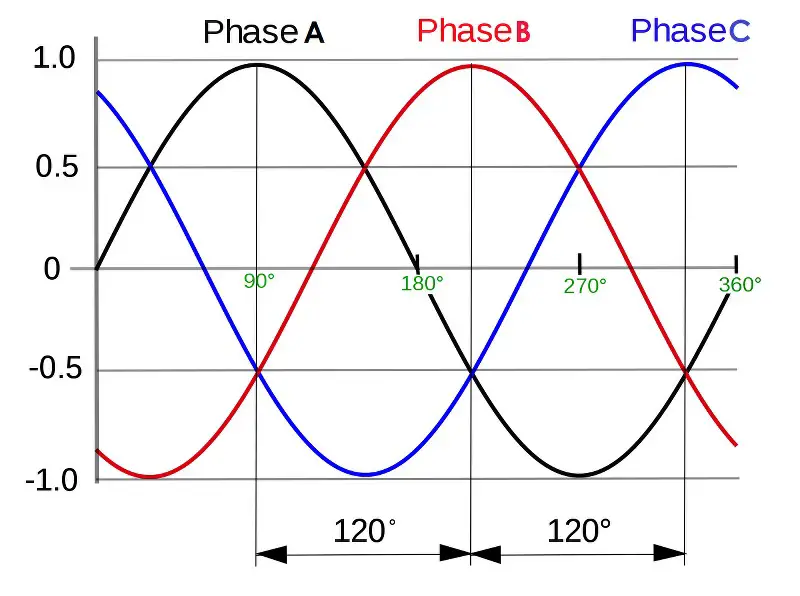

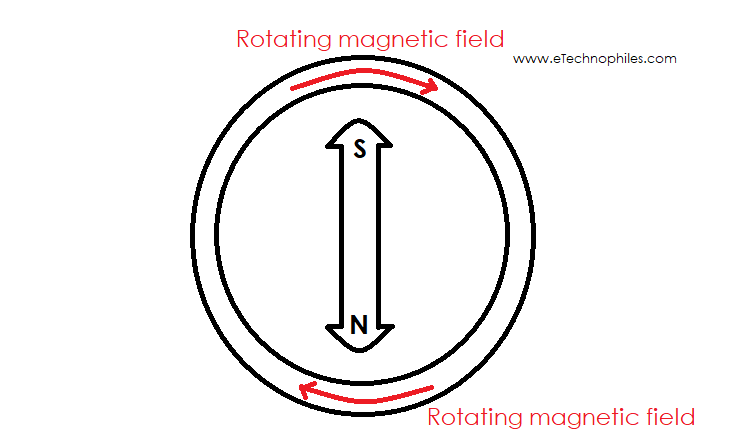

- As we connect a three-phase motor to a three-phase supply source, a magnetic field gets formed. This magnetic field automatically starts rotating inside the armature. It then interacts with the rotor conductors and creates a starting torque for the rotor. So, here, no external aid is required to run the motor. Hence, this is a self-starting motor.

- But, when we excite a single-phase motor with a single-phase AC source, a pulsating magnetic field gets formed. Although the magnetic field has an alternating nature, it remains stationary in space. So, we require additional aid to break the resting inertia and create a starting torque. Hence, this is not a self-starting motor.

Starting torque

The starting torque in the case of a single-phase induction motor is low. Hence it is used to meet load demands with low power requirements. The starting torque in the case of a three-phase induction motor is high. Hence it is used to meet the demand of high power loads.

Efficiency

In a single-phase motor, the windings are excited from a single source. As only one winding transfers all the current, the efficiency of this motor is less. While in a three-phase induction motor, three sets of winding carry the current from a three-phase source. Hence, it increases the efficiency of the motor.

Size of the motor

If we select the same power and voltage rating for both the induction motors, the size of a three-phase induction motor will be less to meet the demand. But, to meet the same load demand using a single-phase induction motor, we require a motor bigger in size than a three-phase motor.

Types

Based on the starting methods, there are five types of single-phase induction motors. These are Resistance-start, Capacitor-start, Capacitor-start Capacitor-run, Permanent capacitor, and shaded pole motor.

Based on the rotor type, there are two types of three-phase induction motors. These are the Squirrel cage type and Wound type induction motor.

Repair and Maintenance

Due to a simple structure, the single-phase induction motors are easy to repair if any component gets damaged. But, due to their complex construction, the three-phase induction motors are difficult to repair.

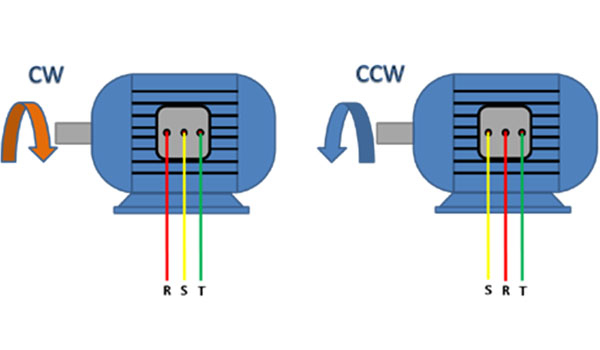

Rotation direction

- For a three-phase induction motor, it is easy to change the direction of rotation. By interchanging two windings (out of three) connected to the stator, the motor reverses its direction of rotation.

**Image courtesy: My Electrical Diary

- But for a single-phase induction motor, there is no practical way to achieve this. As the nature of single-phase AC supply is alternating, changing the polarity will not cause anything. Instead, we have to open the motor and interchange the primary and auxiliary winding of the motor. So, changing the direction of rotation is possible, but not in a practical way.

Cost

A single-phase induction motor uses only one set of windings, while a three-phase induction motor uses three sets of windings. So, the copper requirement in a three-phase induction motor is more, which increases the motor’s cost.

Applications

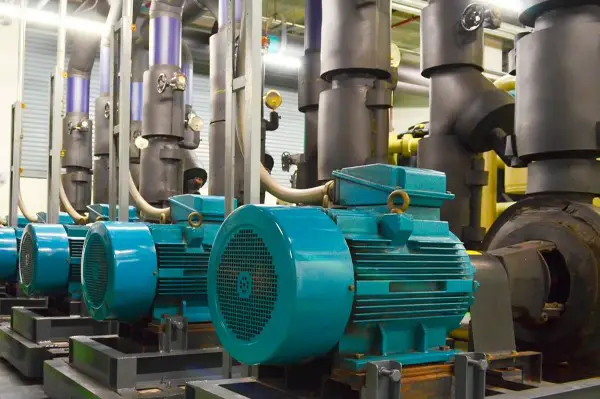

Due to a low starting and running torque, a single-phase induction motor is only suitable for domestic applications, viz, blowers, mixer grinders, fans, compressors, vacuum cleaners, washing machines, etc.

And because of higher operating torque, the three-phase induction motor is suitable for industrial and commercial loads as they require more power.

Reliability

From the above-discussed points, the conclusion comes out that a single-phase induction motor is more reliable than a three-phase induction motor.

Generally, if there is three-phase power supply, try to use three-phase motor, because the three-phase motor with the same power has the advantages of small volume, light weight, low noise, low price and high torque. Interesting article, thank you for sharing.